Inspection and control in production

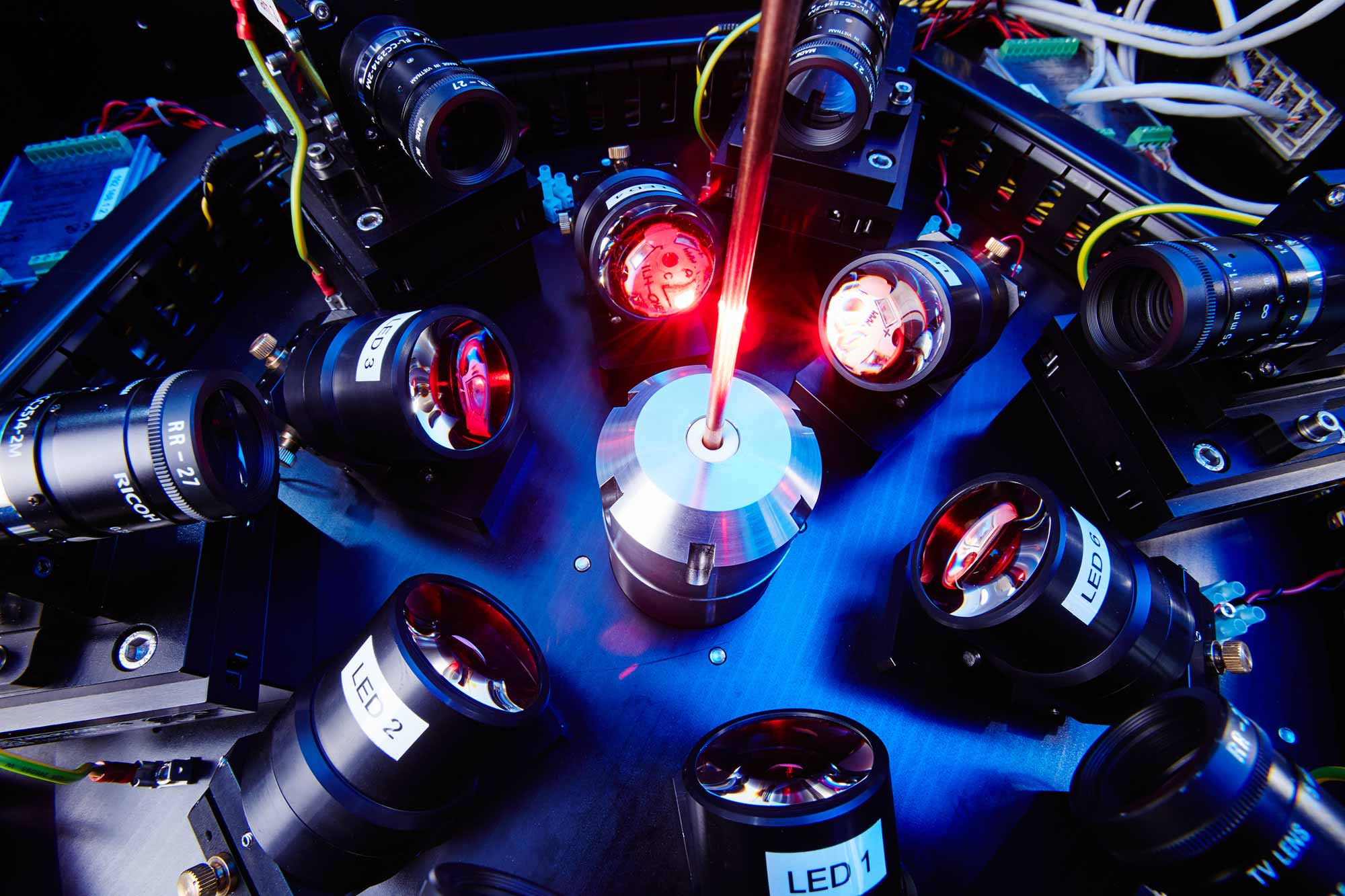

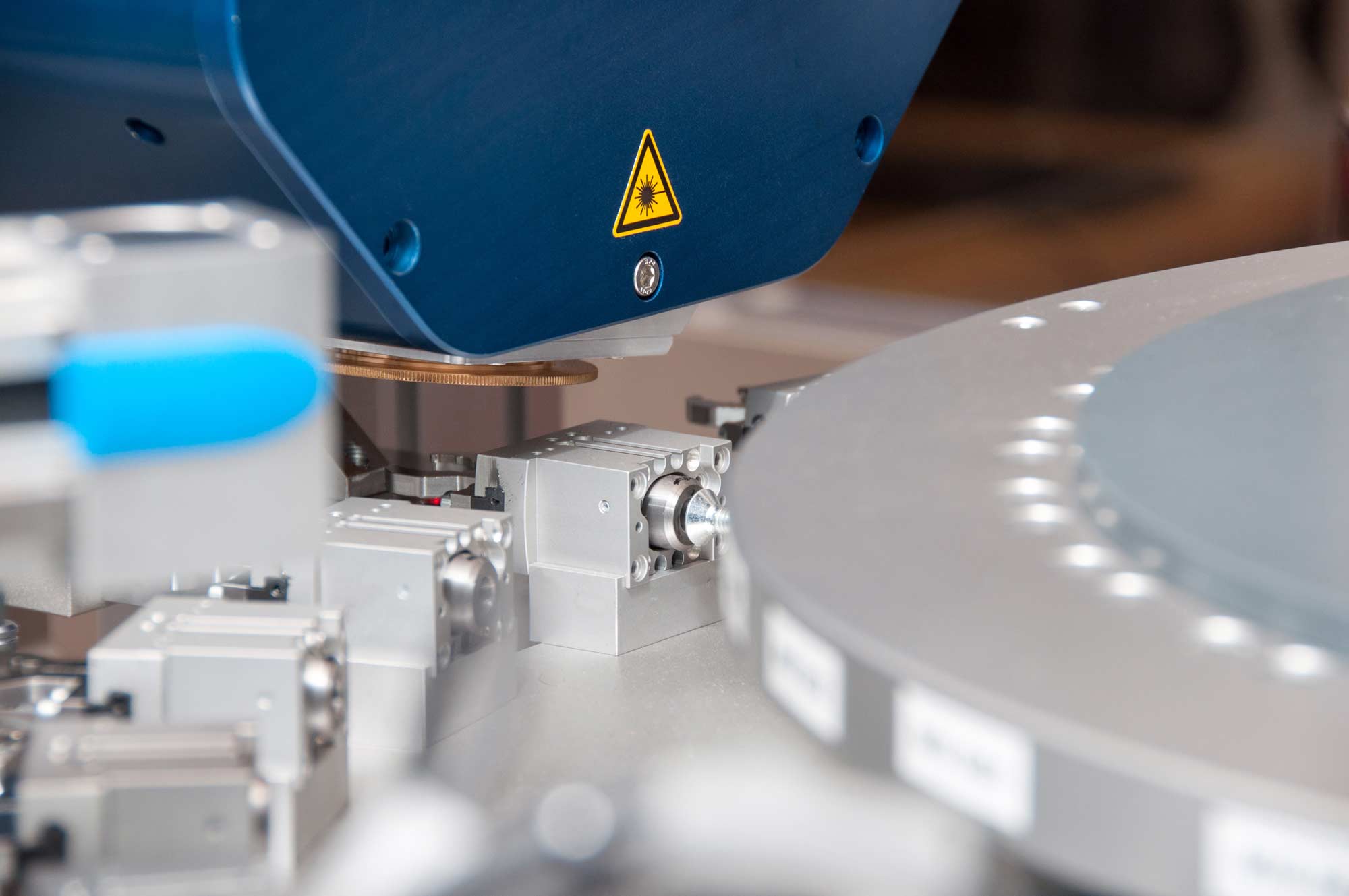

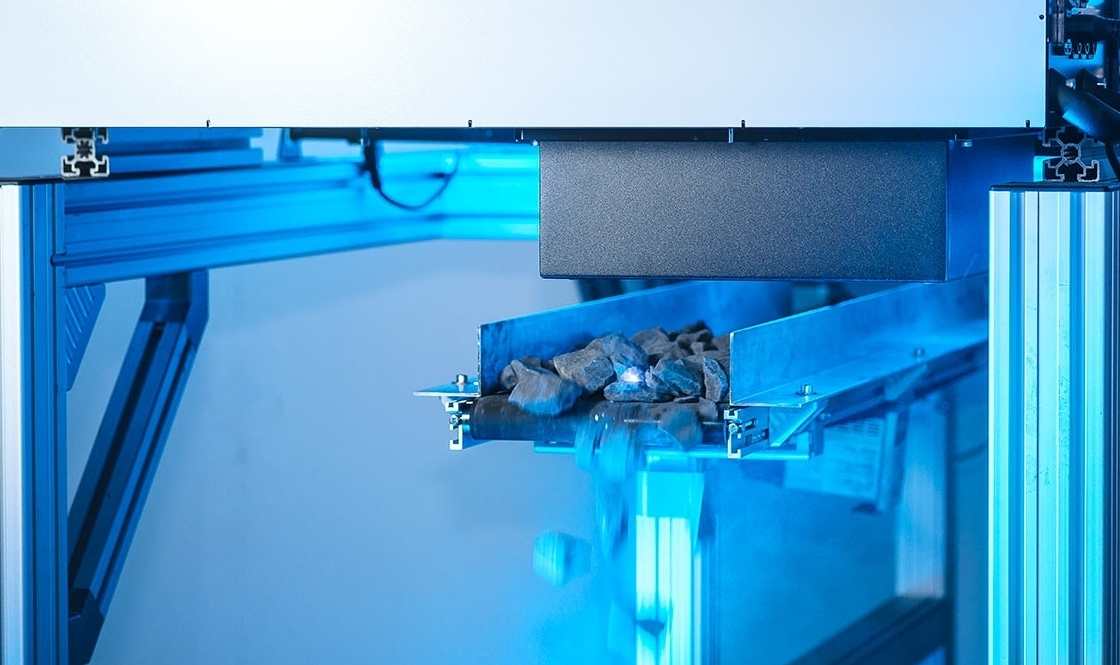

Inline measuring technology provides useful data for controlling quality and for optimizing industrial processes. It plays an increasingly important role in industrial production against the backdrop of Industry 4.0. Fraunhofer IPM develops optical systems and imaging techniques for measuring surfaces and 3D structures. The systems detect very small impurities or defects, even at high production speeds, or identify components by their surface structure. The turnkey measurement systems are designed robustly for use in industrial production.