Thermoelectric temperature control for motor spindle in high-precision machine tools

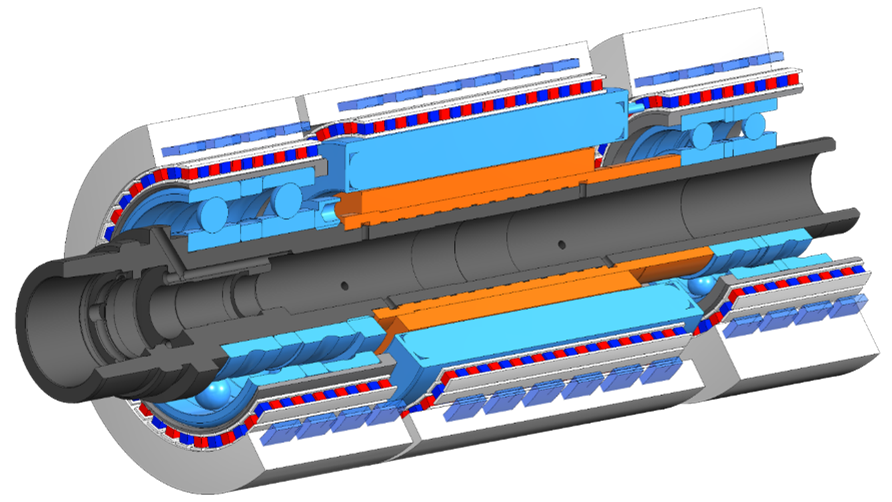

The objective of the Spin-TEC project is to improve the thermal stability of motor spindles in machine tools and thus their machining accuracy.

Precision machining of high-tech components places high demands on dimensional accuracy: components for medical technology, the aerospace industry or toolmaking, for example, must be manufactured with sub-micrometer precision. The thermal behavior of the motor spindles in the machine tool plays a decisive role when it comes to the machining accuracy. As a result of the electrical and mechanical power losses of the motor and its bearings, heat flows are induced into the shaft and housing of the spindles, for example. This leads to rising temperatures and consequently to thermally induced deformations, with a negative impact on the working accuracy.

To date, long warm-up times have been necessary to achieve a thermally stable state of the machine tool. This is the only way to ensure that production tolerances can be maintained. Nonetheless, fluctuations in the induced heat flow and the resulting thermally induced displacement are unavoidable during operation, for example due to tool and workpiece changes and adjustments to the spindle speed.

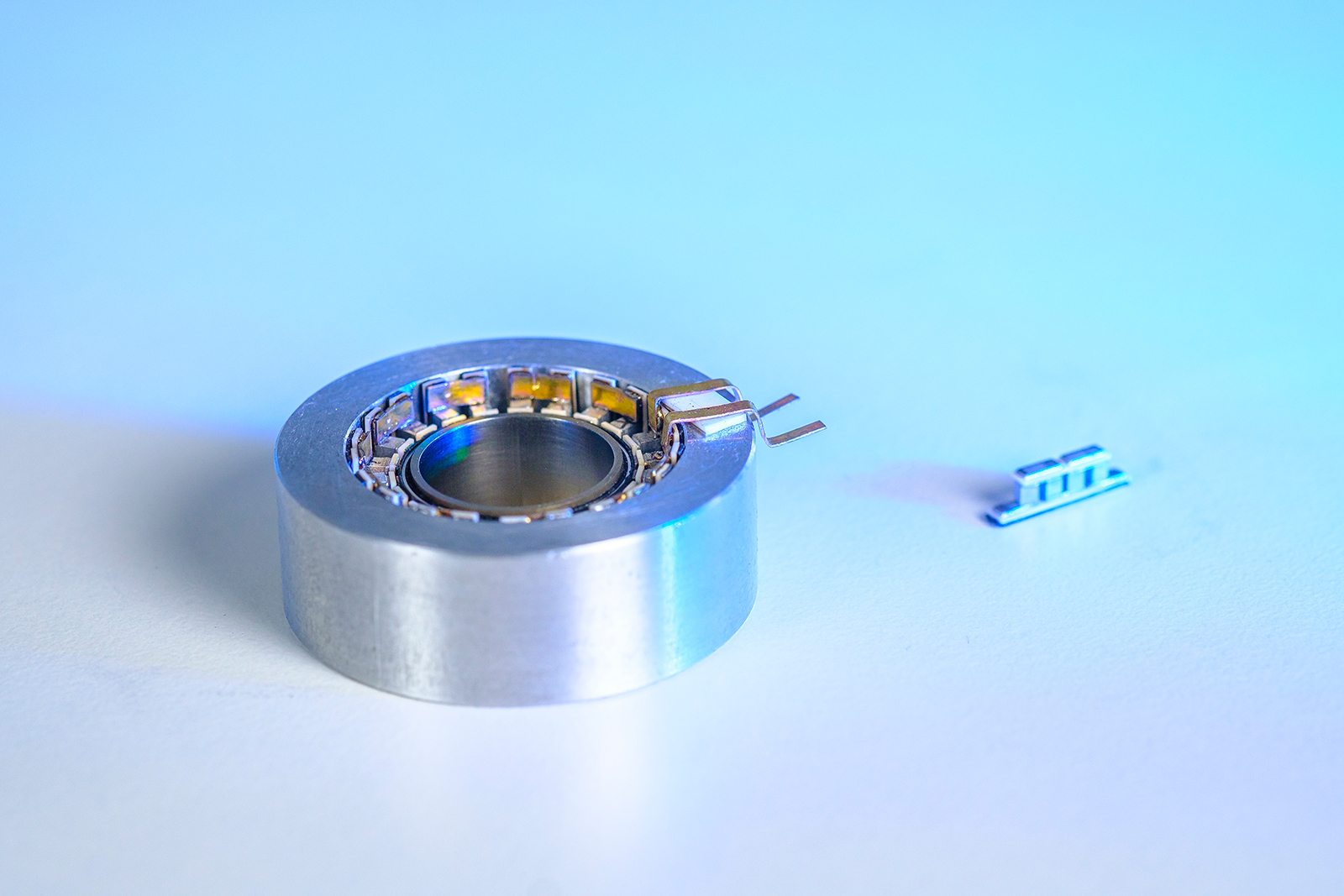

Tubular Peltier modules ensure regulated temperature control of bearings and motor

In the Spin-TEC project, the project partners are developing a new type of thermoelectrically temperature-controlled motor spindle. At the heart of the concept are tubular Peltier modules, which are integrated between heat sources and heat sinks to enable temperature control of the bearings and motor. This increases the thermal stability of motor spindles and reduces their warm-up time compared to the state of the art technology. The thermoelectrically temperature-controlled motor spindle offers the potential to increase machining accuracy and improve the productivity of machining processes.