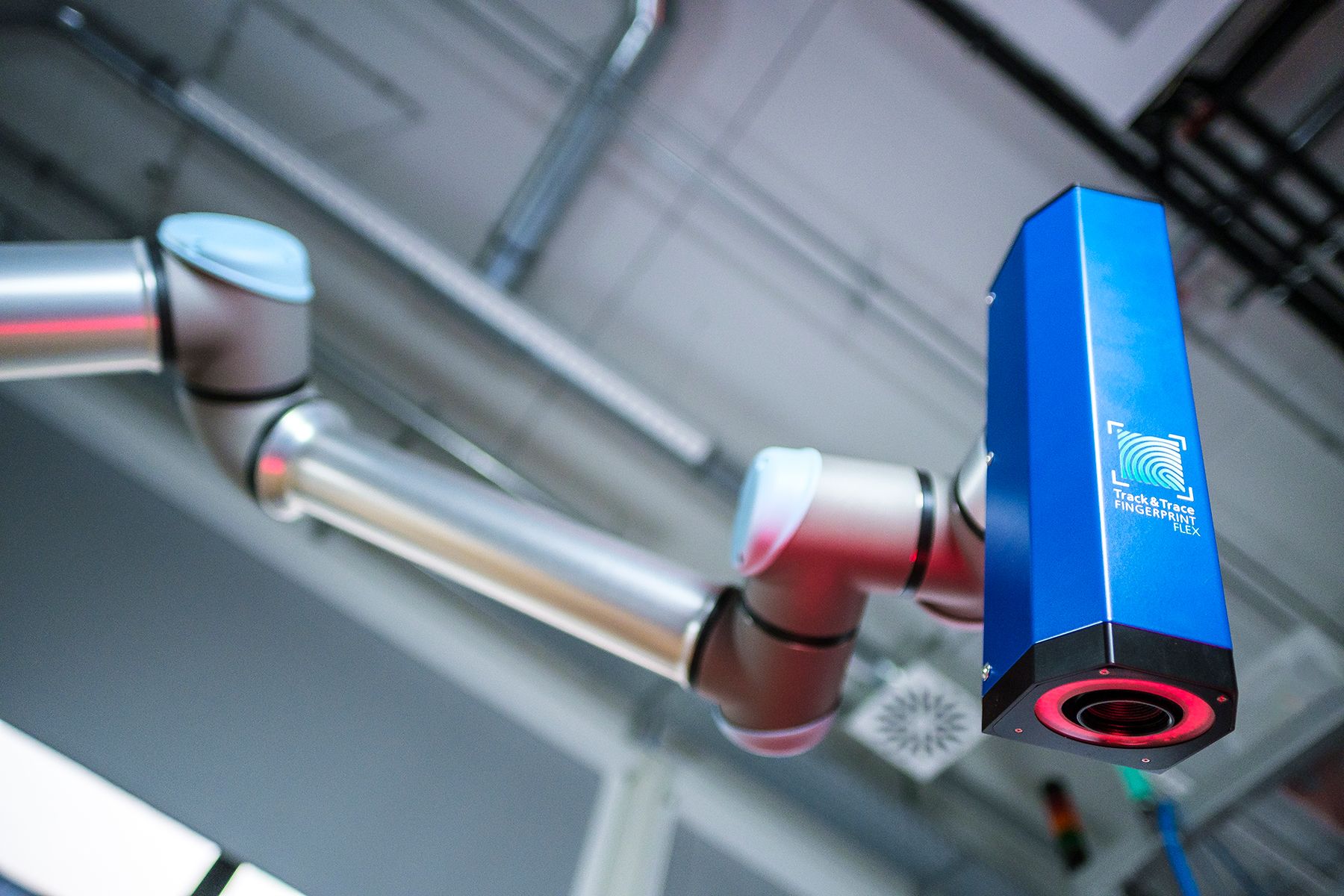

Mobile system for marker-free component identification on the production site

To optimize complex manufacturing processes, flexible systems are needed that reliably identify components anywhere and at any time. Track & Trace Fingerprint Flex by Fraunhofer IPM makes use the component’s individual surface microstructure as a marker for component identification and traceability. In contrast to Track & Trace Fingerprint Inline, which is permanently installed in the production line, Track & Trace Fingerprint Flex is designed for flexible component identification outside of fully automized manufacturing lines.

What is the idea behind Track & Trace Fingerprint?

On closer inspection, almost all technical surfaces reveal individual, incidental characteristics such as microstructures or interwoven colors. The Track & Trace Fingerprint Inline camera system takes high-resolution images of defined areas on the component’s surface. The specific structural patterns captured by the image and the way in which they are positioned relative to each other is used to generate a characteristic bit sequence, i. e. the fingerprint code. This fingerprint code is then stored in a database, combined with an individual ID. This process can be repeated to identify the component at a later date by taking an image of the very same component area and matching the newly generated fingerprint code to the codes stored in the database. If this there is a match, the component is clearly identified by the respective ID, which also allows attributing additional information such as measurement or production data to any individual component.

The marker-free Track & Trace Fingerprint technology by Fraunhofer IPM enables identification and traceability even of mass-produced parts, where markers such as data matrix codes are either too expensive to apply or technically simply not feasible. With Track & Trace Fingerprint, there no additional costs per unit and the functionality of the component is not impaired.

Suitable for a wide range of materials, component geometries and sizes

Track & Trace Fingerprint Inline has been designed to enable traceability of different component sizes and geometries, from circuit boards with very small detection areas to cross-sectional areas of steel profiles. The method also works for rotationally symmetrical components and even their curved lateral surfaces. A wide range of materials, from plastics to precision machined aluminum, cast iron and varnished surfaces can be identified.