Materials testing with LIBS

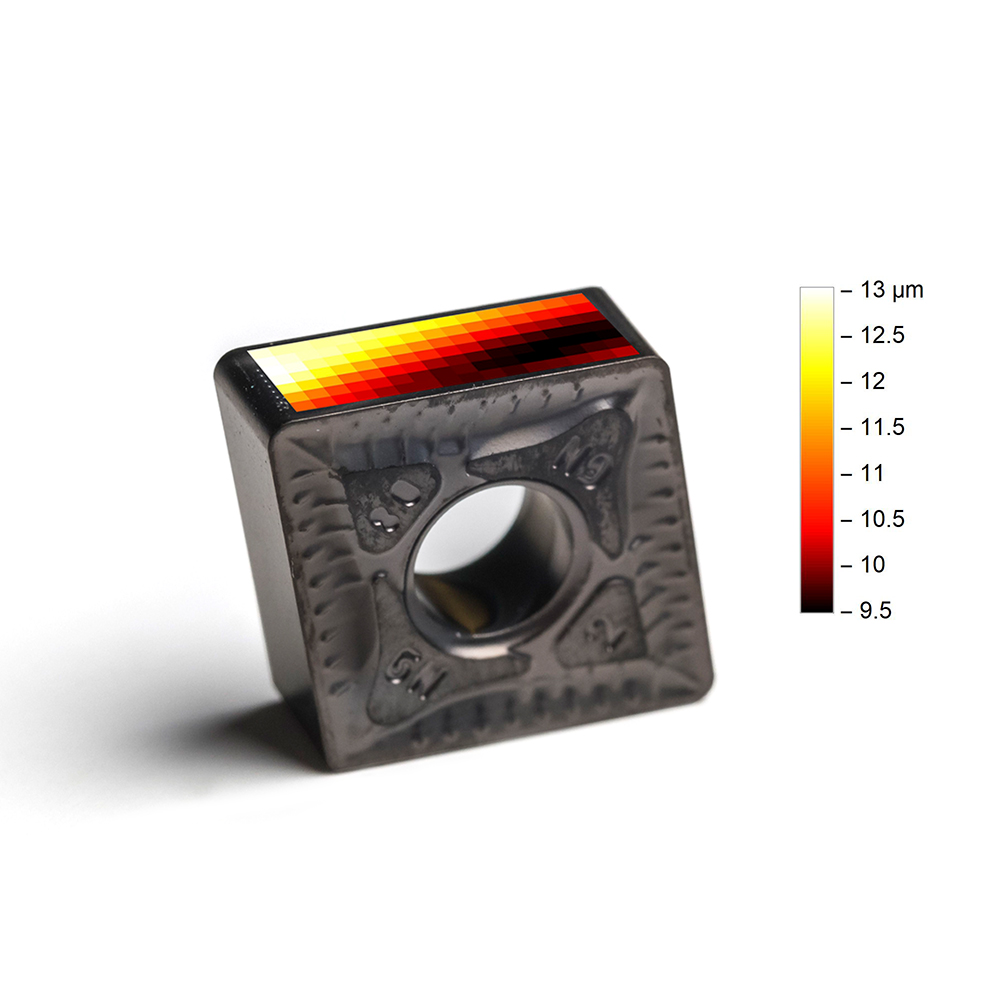

Many production processes require the thickness and composition of coatings or surface materials to be inspected. Fraunhofer IPM relies on laser-induced breakdown spectroscopy (LIBS) to analyze the thickness and elemental composition of coatings and solid materials.

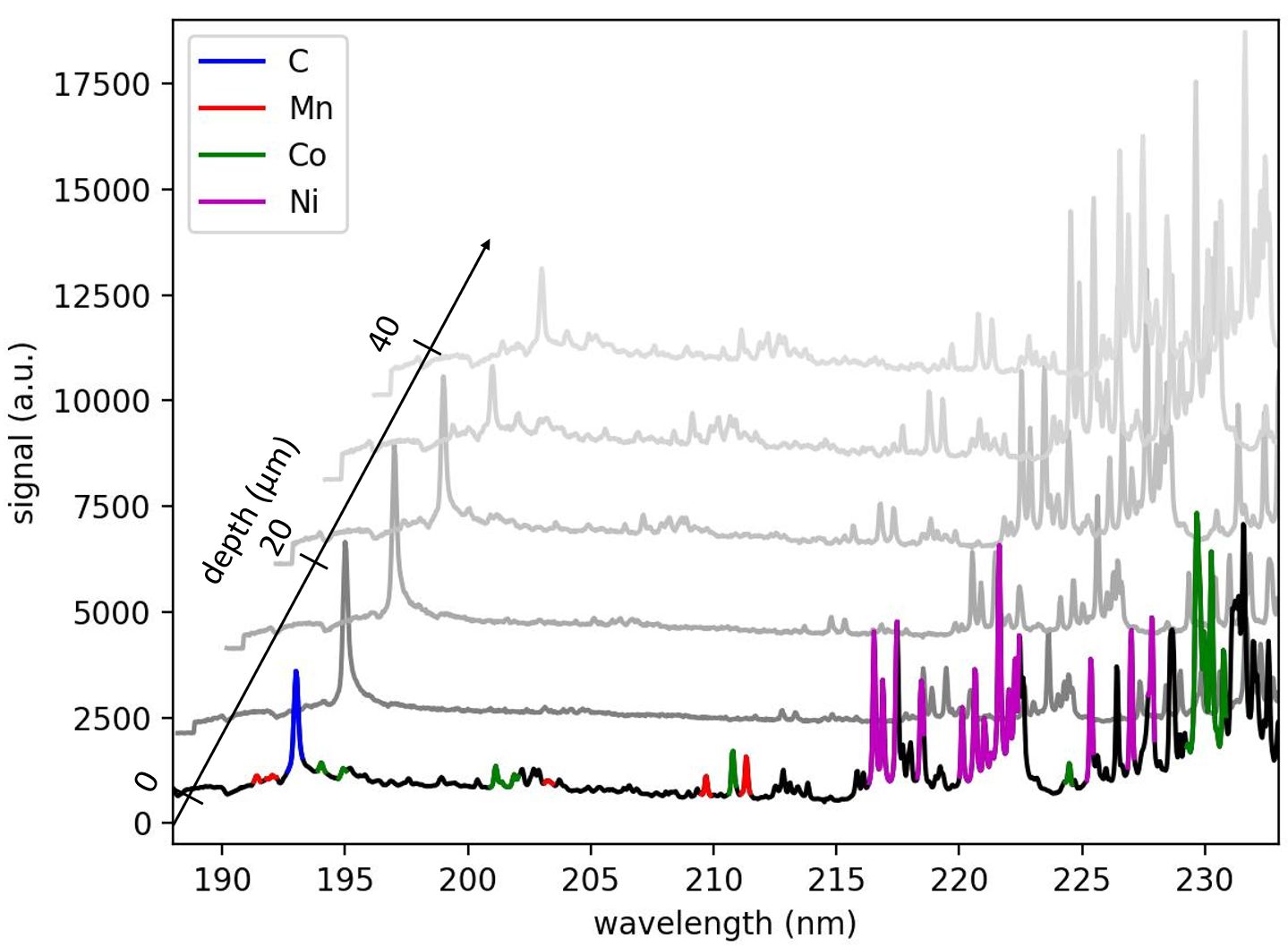

The LIBS method uses a short-pulse laser to transfer a tiny amount of the surface material – usually just a few µm3 – into a plasma for spectral analysis. This plasma emits a material-specific light spectrum. The spectral light distribution is recorded in real time. The element distribution at the measuring point is determined on the basis of the spectral data.

The LIBS method is suitable for alloy analysis, coating inspection and layer thickness measurement within the range of nanometers to 100 micrometers. It also enables depth-resolved measurement of element composition.

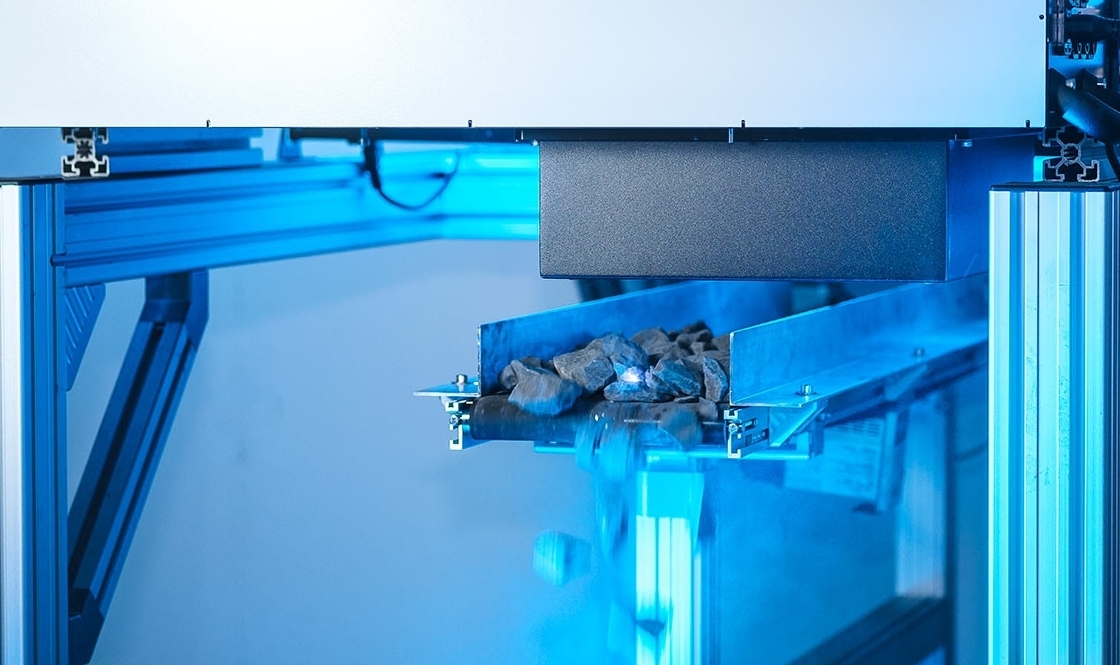

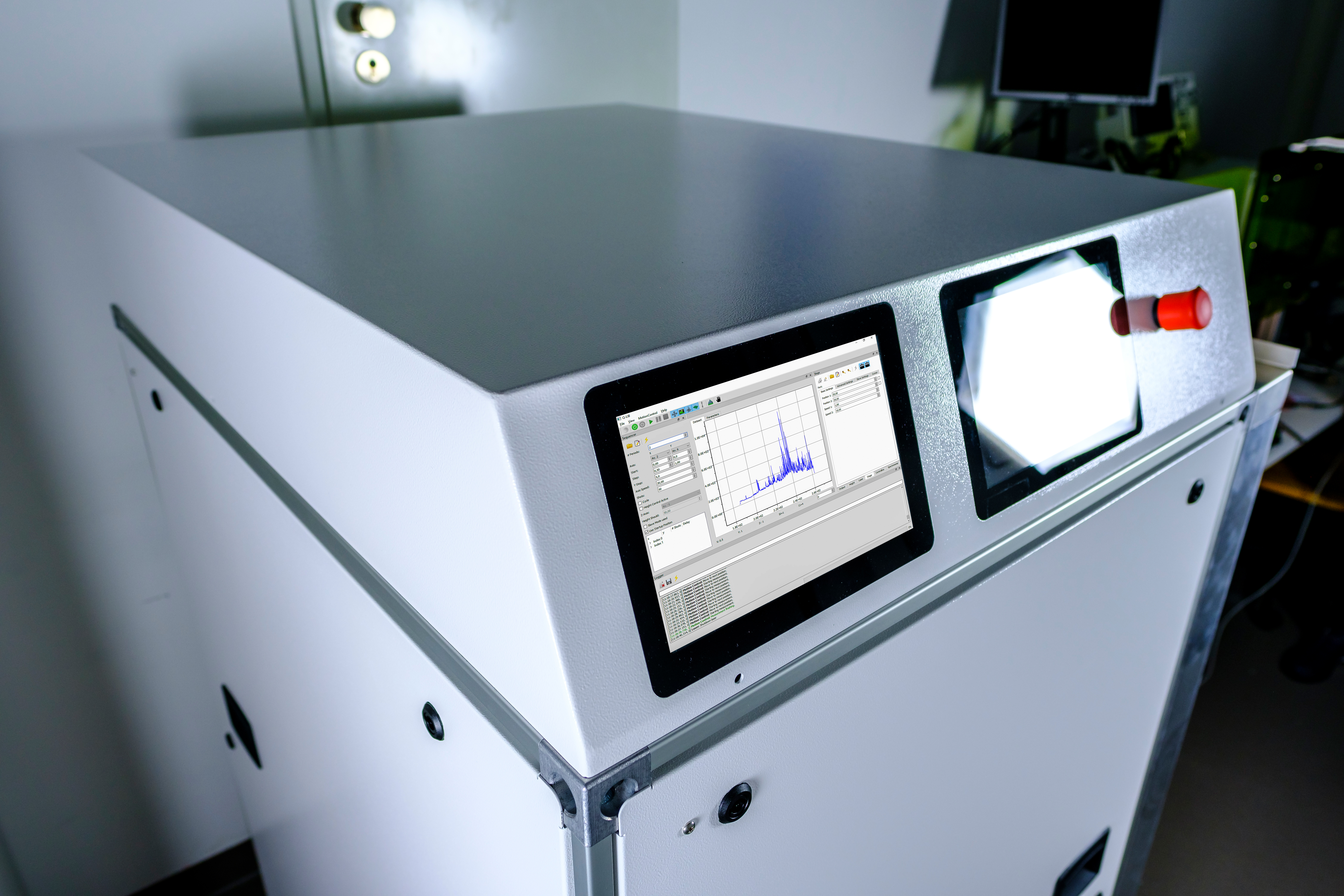

The ANALIZEsingle and ANALIZEmulti systems for optical surface analysis capture the element composition at one point on the component surface within milliseconds per measuring point. The systems are suitable for measuring the composition and thickness of coatings as well as for determining the composition of bulk materials.