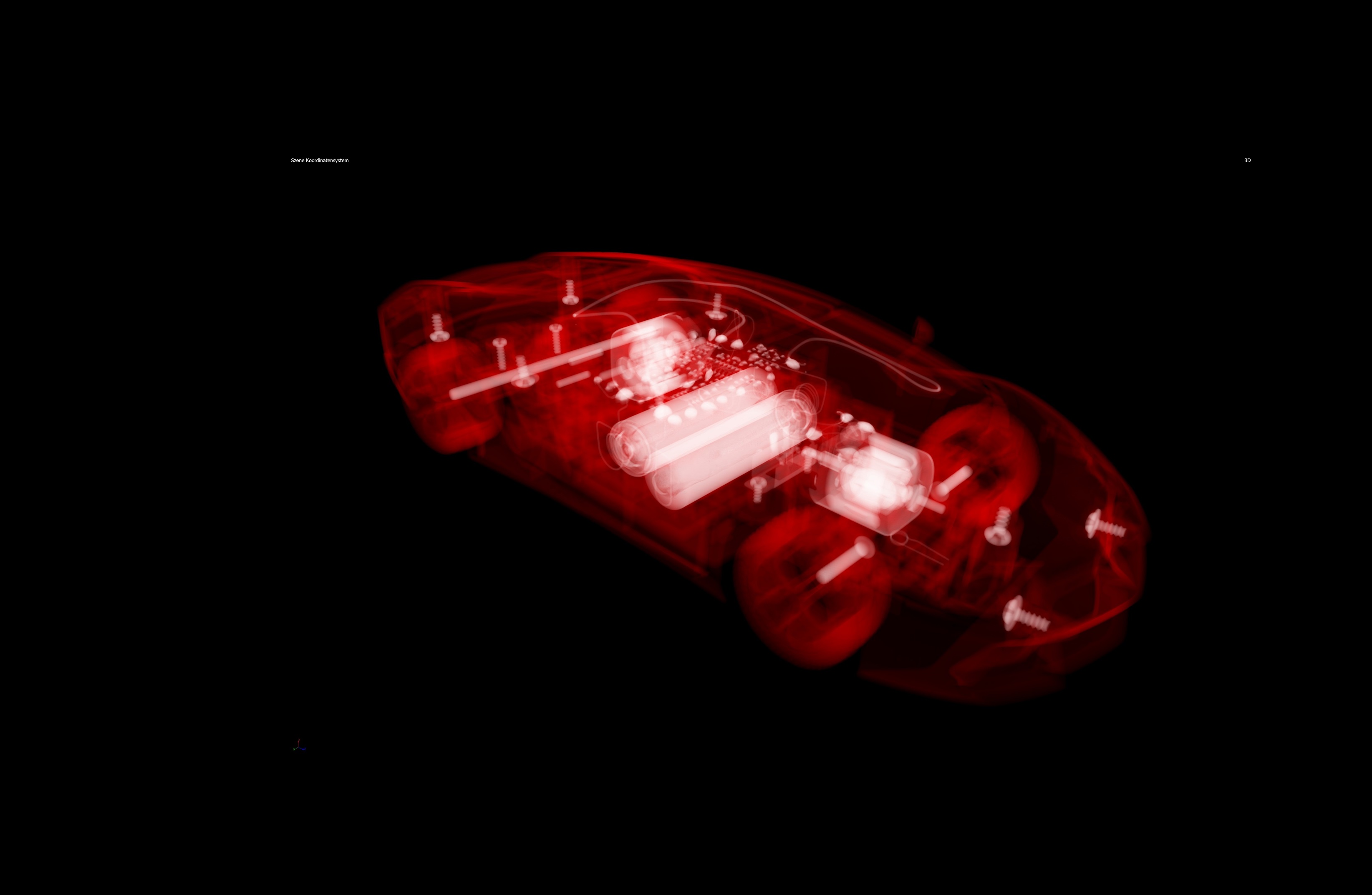

3D computer tomography (3D-CT)

Fraunhofer IPM makes use of its excellent technical equipment for tomography against a background of decades of experience in thermal engineering, Peltier cooling, heat pipes, sensor technology and failure analysis of functional materials and components. Our laboratories are well equipped for thermophysical analyses (i.e. measurement of thermal conductivity, heat capacity or phase transitions), measurement of electrical properties or investigation of heat pipes, Peltier modules, etc.

Based on this experience, we are able to realize entire analytical chains that are tailored to the individual questions of our clientele. For example, we can directly investigate how defects detected during structural analysis affect thermophysical and electrical properties. Thanks to the X-ray detector's high dynamics, fluids can be made visible and fluidic processes can be monitored in real time in a component, e.g. in heat exchangers and coolers. X-ray imaging of components is also possible while the device is operated »live« under near-operational conditions such as defined temperature, humidity, gas composition or with cooling water (»in-situ«). If necessary, we manufacture special, sealed measuring cells for this purpose.

For our customers we develop individual solutions for non-destructive analyses in the areas of development, product control and failure analysis. Tomography has proven to be an ideal tool in the development of new manufacturing processes such as 3D printing as the dimension, shape and structure of manufactured components can be compared very quickly with nominal values. Thus, development and production can be quickly adjusted and – if component failure should still occur – the defects can be analyzed quickly and effectively.

Express service

Experience has taught us: Time matters in the search for defects, component faults and in the development of processes. We therefore respond quickly to inquiries and, if required, deliver an analysis result for your parts within a few days.