Image capturing plays a key role in optical measurement technology. Image information of objects or scenarios is the basis for numerous measurement technology applications, such as infrastructure inspections, traffic route planning or determining vegetation vitality. Cameras are at the heart of image capturing in our mobile measurement systems. We also use laser scanners to create photo-realistic images of surfaces by combining intensity and distance information.

Image acquisition | Intensity measurement

Selecting the ideal camera system for various image capturing requirements

Our measurement systems come with a variety of different camera options – from smartphone cameras to extremely robust industrial cameras, and from ultraviolet to mid-infrared-spectrum cameras. Cameras form the basis of our image capturing systems. They provide data for a wide range of applications, including geometry capturing and analysis of objects, human motion pattern recognition, object recognition in images and for multispectral vegetation analysis.

Capturing surface textures with high-resolution – without using a camera

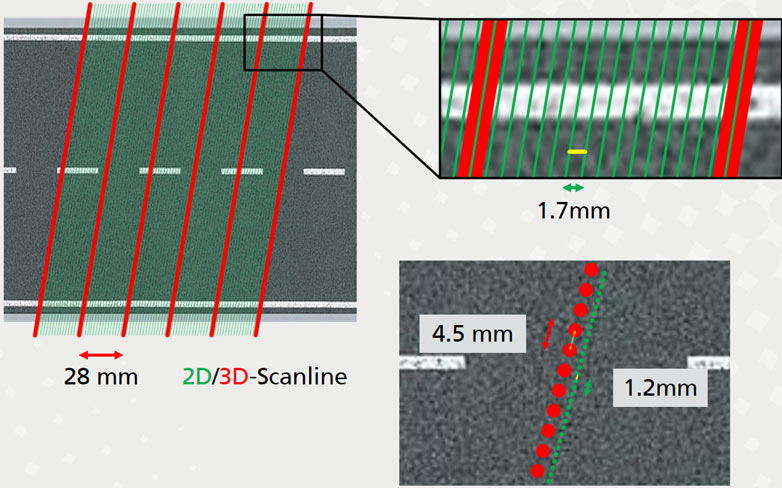

In addition to the 3D geometry of objects, their surface is also relevant, with precision requirements down to the sub-millimeter range. Up to now, this type of imaging from mobile platforms moving at a typical speed of 80 km/h required special camera systems and strong active lighting. The focus range and field of view of such optical setups had significant restrictions. The resulting camera images have to be stitched together in a painstaking process.

Photo-realistic images by 2D intensity scan combined with 3D distance measurement

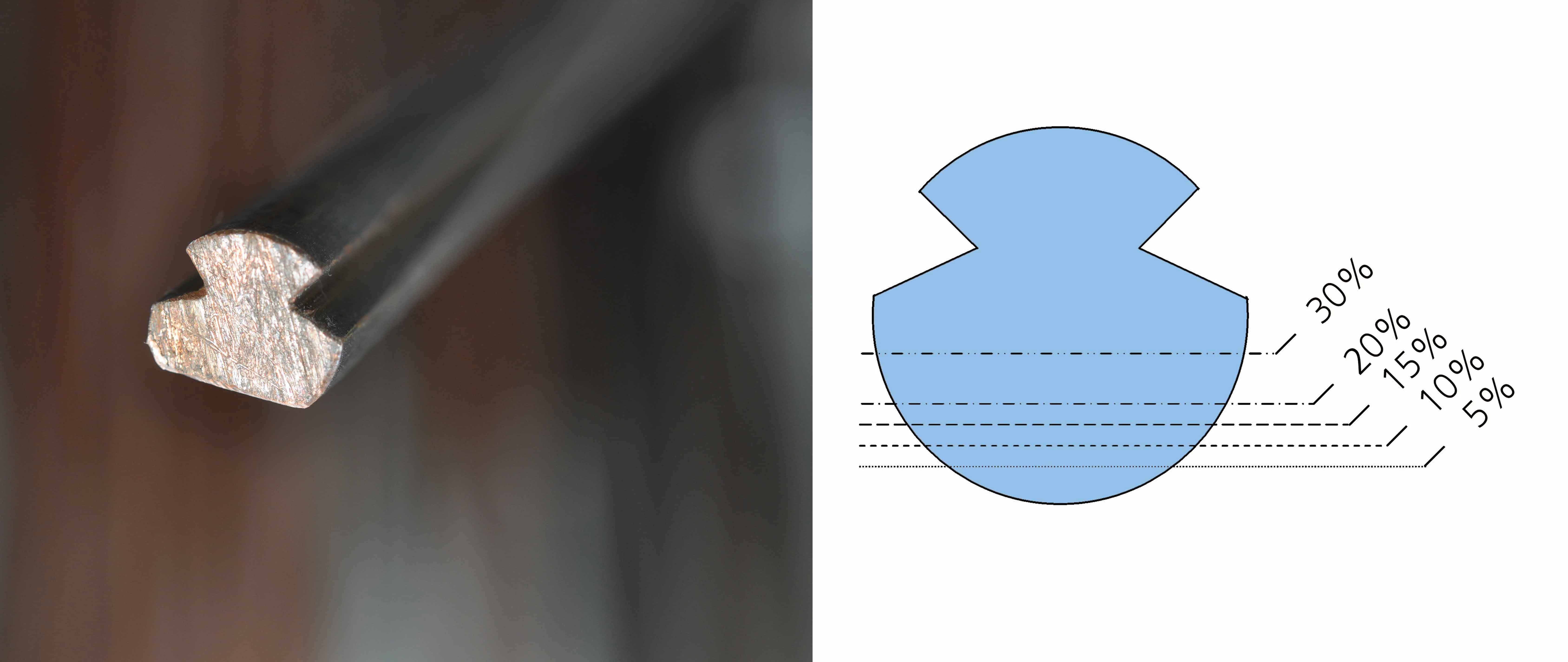

Fraunhofer IPM has developed and patented a novel, laser-based technology that can simultaneously capture 3D images and high-resolution 2D surface images – no camera needed. This concept combines an intensity scanner for 2D information with a distance scanner for 3D information in one single optical setup. The laser scanner units are calibrated with each other and can fit into a compact housing. The resolution of the 2D intensity image is 16 times higher than that of the 3D image.

Deep depth of field under any lighting conditions

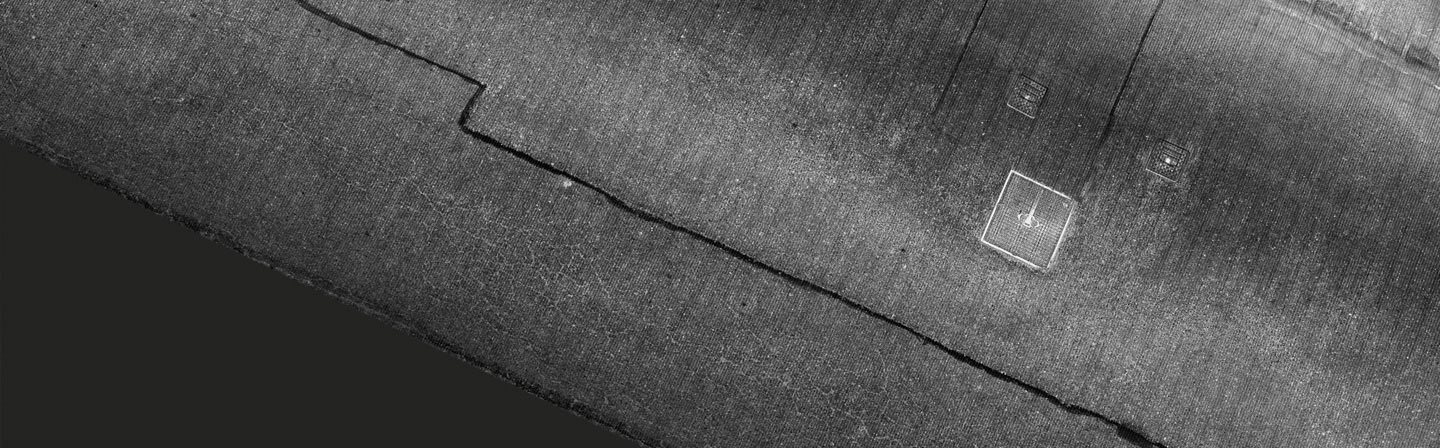

Photo-realistic imaging based on laser scanner data has three key benefits: It is completely independent of lighting conditions and has a deep depth of field. Hardware-only calibration eliminates the need for time-consuming post-processing, such as stitching. This technology can be used in applications such as detecting damage in asphalt or concrete in the sub-millimeter range, even from carrier platforms traveling faster than 80 km/h.

Photogrammetry: cost-effective alternative to 3D surface reconstruction

Photogrammetry provides a cost-effective alternative. Photogrammetry uses images of 3D objects and environment captured from different angles to reconstruct a 3D point cloud, which can then be used to create a dense 3D surface reconstruction.