Deflection units are an important part of our laser scanning systems. They quickly and precisely deflect the laser beam in different directions, enabling the fast and accurate capture of 3D objects. We select the deflection units of our optical measuring systems based on the application and system structure, and adapt them to the conditions and requirements of the measuring task: For example, we use 360° deflection for mobile mapping applications, while capturing undersea infrastructure requires a large and comprehensive deflection.

Rotating mirrors as deflection units: 360° imaging with several hundred Hertz

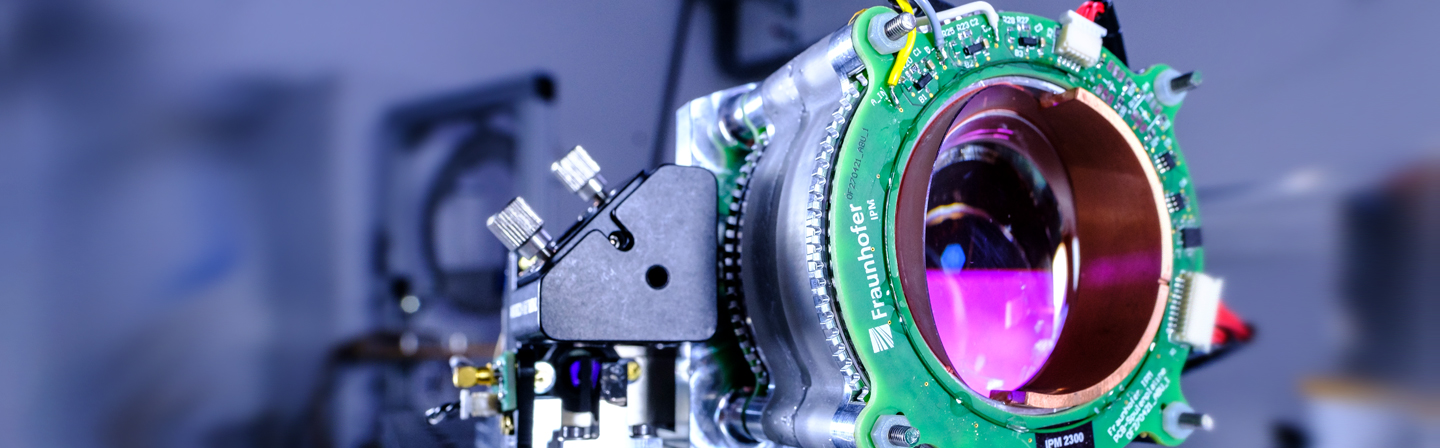

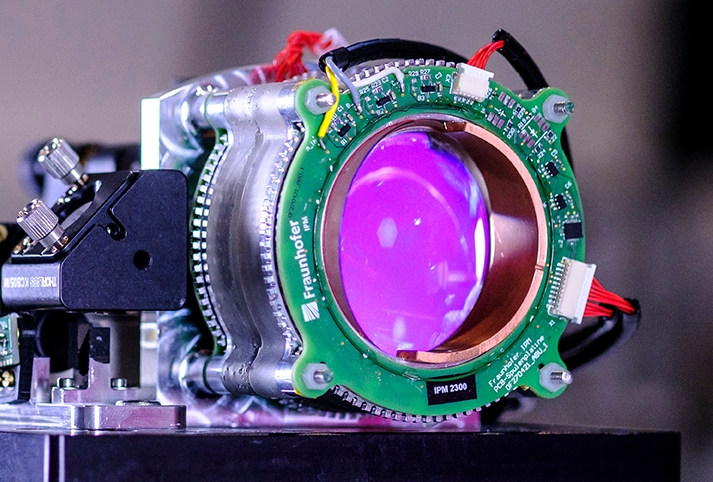

Rotating mirrors allow a deflection speed of several hundred Hertz. Fraunhofer IPM develops and builds a large range of deflection units – from small and light units for drone-based measurement technology to large two-mirror deflection units. The latter enables simultaneous 360° imaging using two laser beams and profile rates of over 500 Hz.

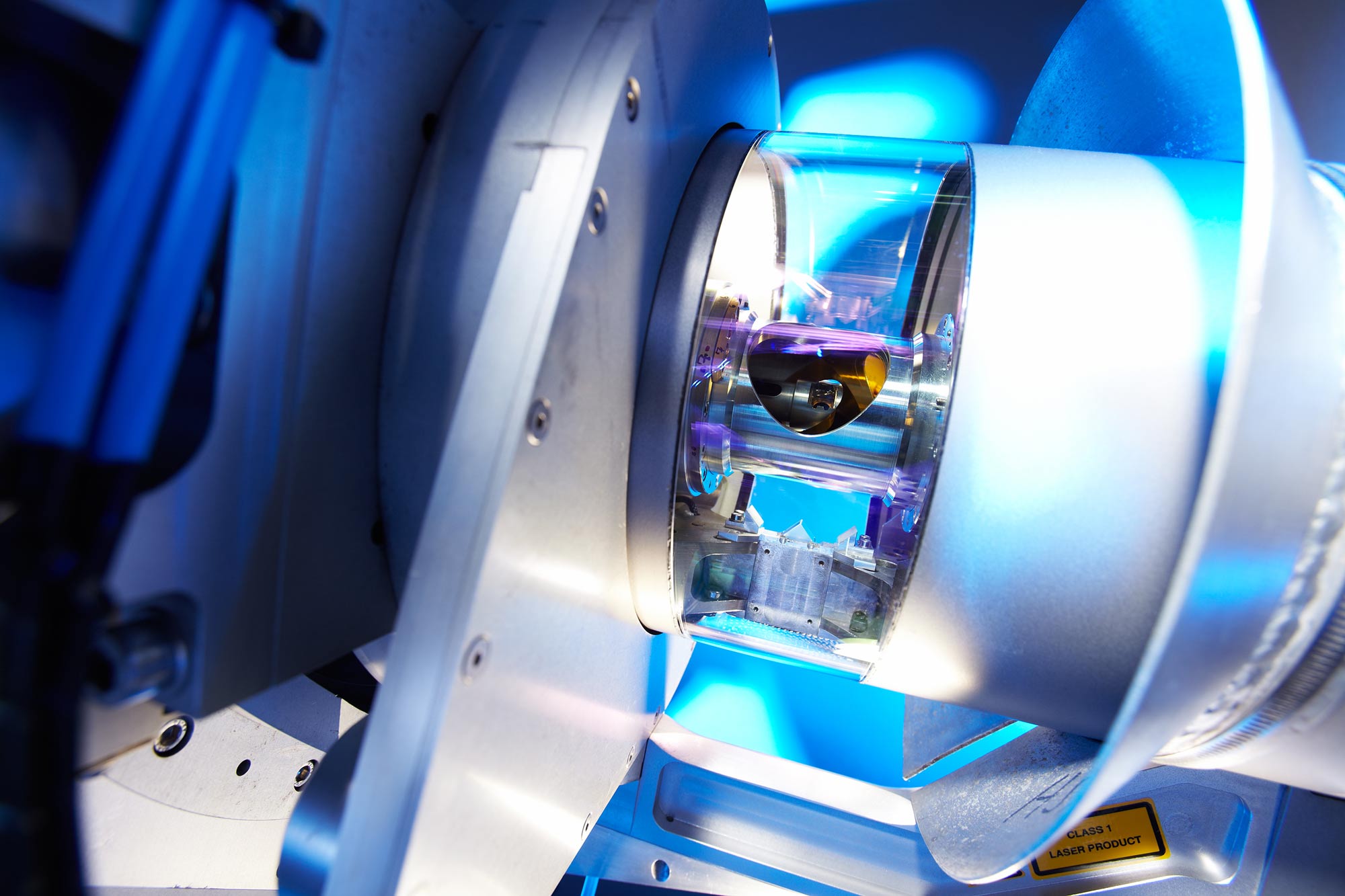

Wedge prism as deflection unit: various scan modes for high flexibility

Wedge prism deflection units allow scan fields to be adjusted. Wedge prisms that can rotate around their own optical axis can help realize various can modes – from point-by-point measurements and line scanning to comprehensive imaging of objects with a stationary scanner. This makes wedge prism deflection units highly flexible and allows the scan fields to be adapted to specific measuring tasks. For example, undersea infrastructure can be comprehensively captured using a tripod, followed by a linear scan of a submarine pipeline from a ROV.

Galvanometric and solid-state deflection units

In addition to mirrors and wedge prisms, we also develop other types of deflection units depending on the measuring task. This includes galvanometric deflection units based on oscillating mirrors and solid-state deflection units based on semiconductor or crystal technology, for example.

Calibration and ray tracing

Any deflection unit is only as good as its calibration: For this reason, development of deflection units includes methods for determining the manufacturing and alignment tolerance using measurement data, and for accurately tracking the laser beam’s measurement position using ray tracing models.

By using different types of individually calibrated deflection units, we can offer customized solutions for a variety of applications, meeting the requirements of deflection speed, resolution and scan field. With our expertise in deflection unit design, we can provide our customers with the ideal solution for their needs.