Exactly positioned – efficiently check and document the position of overhead contact lines

The electrification of existing railway lines is progressing worldwide. New railroad tracks are being equipped as standard with overhead line systems supplying the moving trains with electricity. The overhead contact line has to be installed in a well-defined area with sufficient tension. Incorrect positioning can have fatal consequences. Therefore, the position of the contact wires must be checked at regular intervals with regard to their height and lateral position – if possible quickly and efficiently in regular operation.

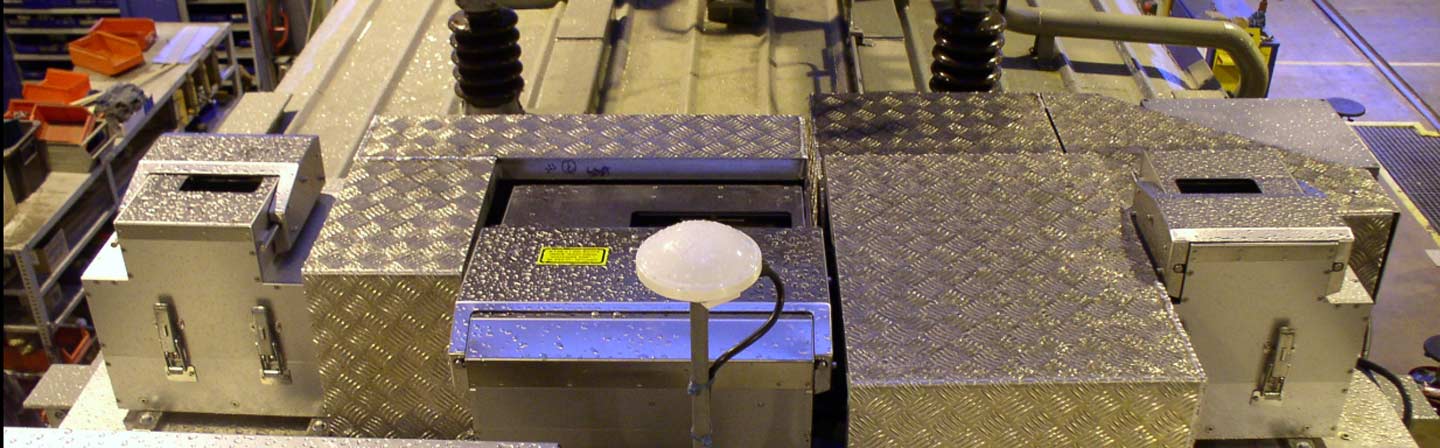

Contact Wire Recording System CRS

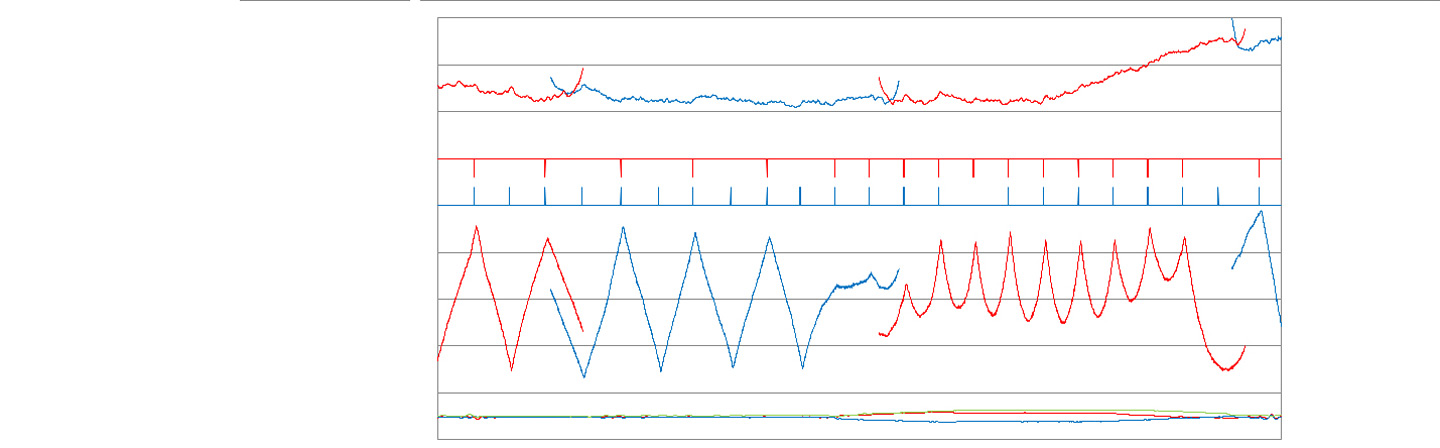

The CRS, developed by Fraunhofer IPM, records the vertical and horizontal position of the contact wires at speeds up to 250 km/h. Mounted on the roof of an inspection car, the laser scanner records the clearance above the car’s rooftop with 400 Hz and yields data on the position of up to eight contact wires simultaneously in real time. The laser measuring system actively illuminates the contact wires from below with a laser and is therefore largely independent of time of day or weather conditions.

The processing and evaluation unit inside the car provides the operating personnel with processed position data – already corrected for the separately recorded rolling movements of the car body. Additional features such as semiautomatic cleaning ensure reliable and low-maintenance operation.

Keeping the entire overhead line in view

The CRS is also part of the multi-sensor system CIS (Contact Wire Inspection System) and its low-speed variant CIS-LS. These systems record contact wire wear and contact wire position simultaneously and, optionally, identify the position of poles.