Stuttgart / April 23, 2024 - April 26, 2024

Control 2024

International trade fair for quality assurance

Fraunhofer IPM at the

Fraunhofer Business Unit VISION Stand 8201 / Hall 8

International trade fair for quality assurance

Fraunhofer IPM at the

Fraunhofer Business Unit VISION Stand 8201 / Hall 8

High-precision 3D inline measurement: Inline inspection of large surfaces with regard to cleanliness and coating. Complete optical inspection of mass-produced components in free fall.

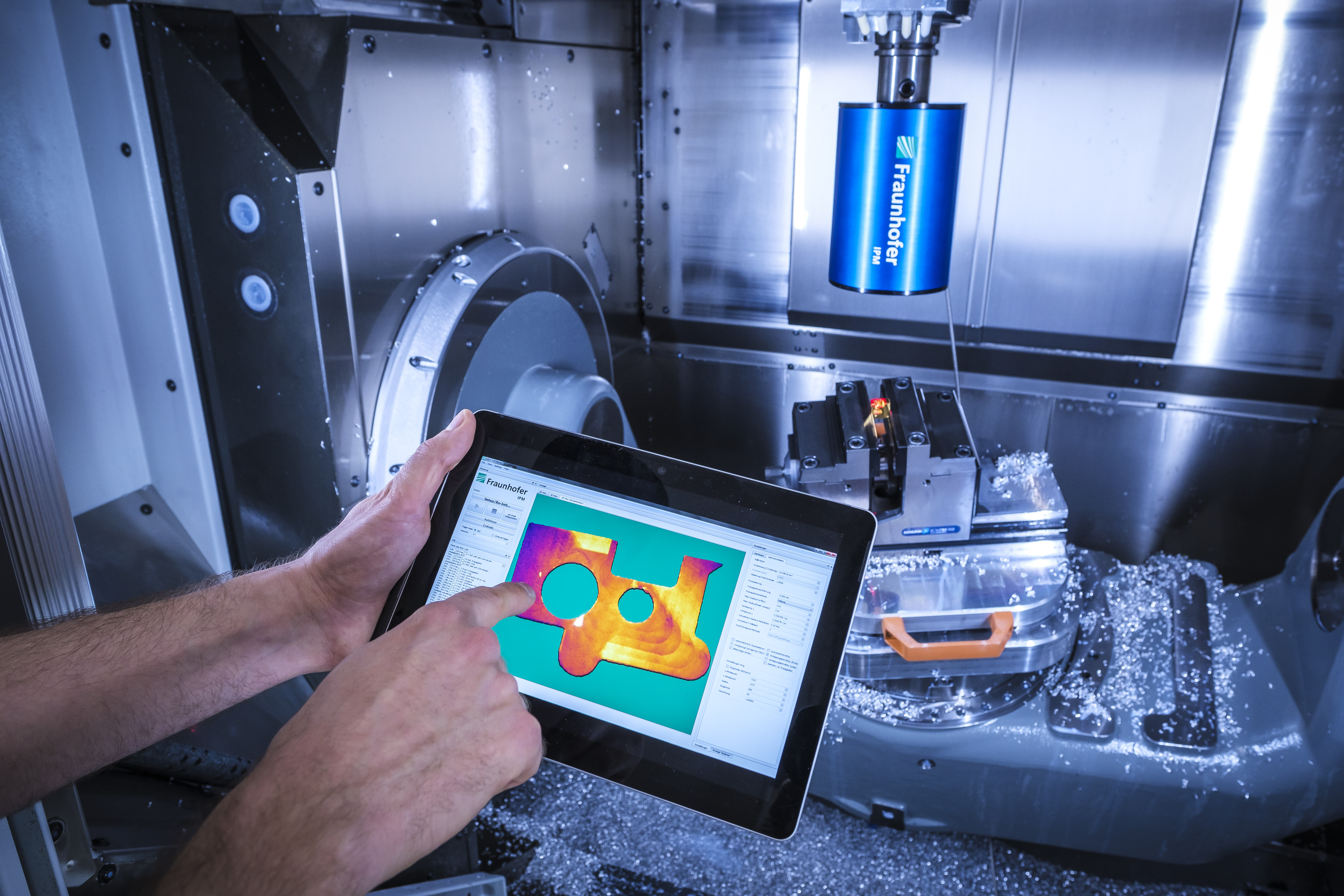

Our systems of the HoloTop sensor family enable fast and highly accurate 3D measurement of component surfaces directly in the production line.

Systems are currently available for measuring surfaces between 15 × 15 mm² and 150 × 125 mm² (flexibly expandable) with lateral resolutions between 3 and 30 µm and accuracies better than 0.2 µm (3σ, under production conditions).

HoloTop systems are used for quality control of precision metal surfaces (e.g. directly in the machine tool - see illustration) or electronic components (microbump structures or high-current circuit boards).

The HoloTop Infinity system presented is able to measure an area of 150 × 125 mm² with 100 million 3D points in under 1 second. The measuring field can be extended as required by additional sensor heads, e.g. with three sensor heads for the full-surface measurement of a bipolar plate. The quality of the measurement data is illustrated using various sample specimens.

We are presenting the fluorescence scanner F-Scanner 2D. It scans the component surface in two spatial directions and generates a complete image of the coating or residual contamination. This makes it possible to identify where and in what quantities organic residues or coatings are visible on the component surface. So, for the first time, the surface coating can be analyzed quantitatively even on 3D objects of any shape. The system is suitable for preliminary inspection, for flexible quality inspection of series components and as an inspection system in the production line. The F-Scanner-2D can be used as a stand-alone device or integrated into a production line.

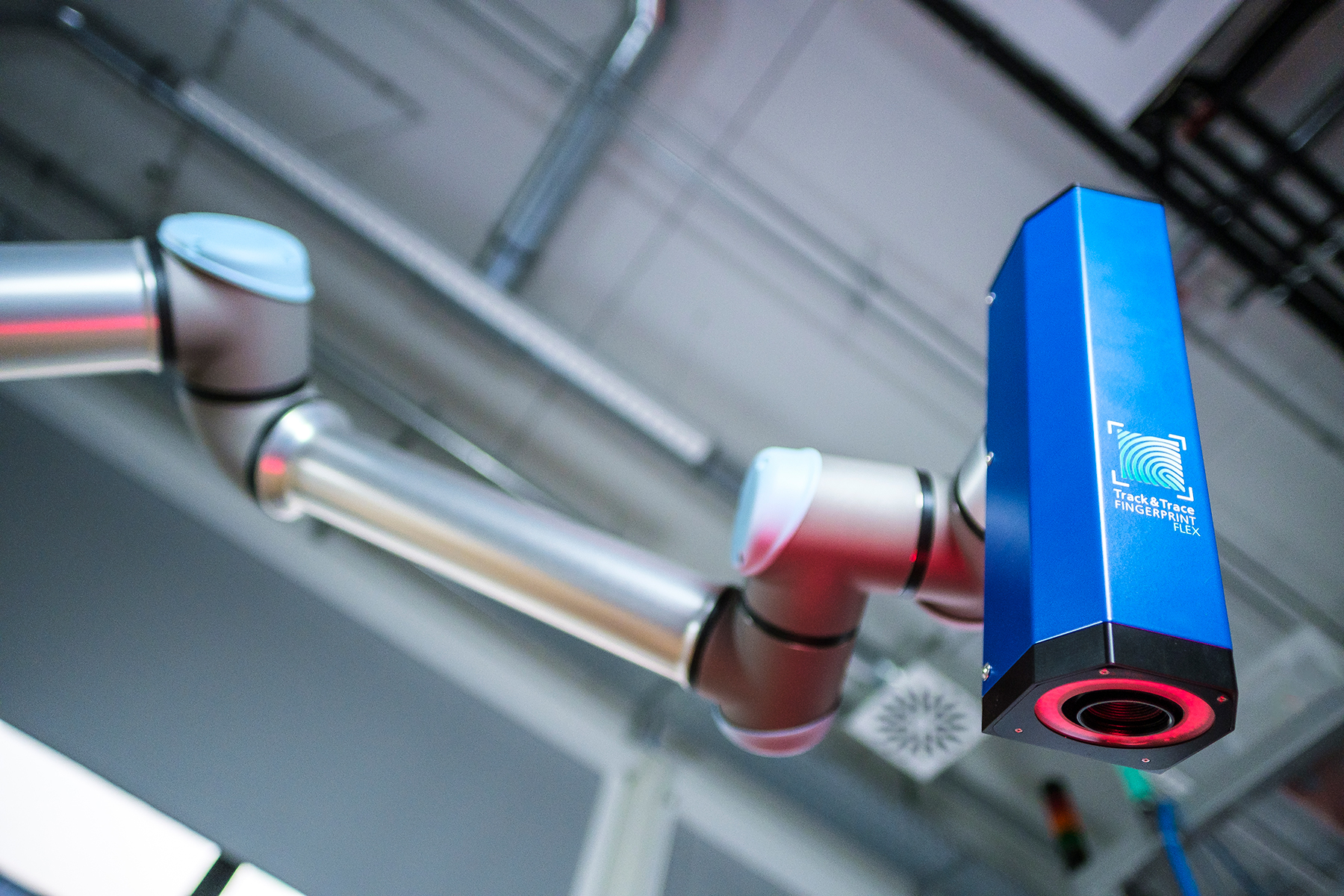

»Track & Trace Fingerprint Flex« has been developed as an extension of the Track & Trace system for tracking mass-produced components.

Workpieces or load carriers in the logistics chain are recognized without additional markings, solely on the basis of the individual component surface, which provides a "unique fingerprint" for each component.

»Track & Trace Fingerprint Flex« is designed for mobile, flexible use outside the production line. The battery-operated, portable system can be used with robots or as a hand-held device for the random identification of components at any position in the production process - for example in assembly, logistics or quality assurance.