Real-time analysis of plasma-induced discharges

RAPID-LIBS is an ultra-fast spectroscopy module created for integration into existing laser processing systems. When drilling, ablating, thinning, or cutting materials with lasers, it is important to perform the ablation to a defined depth at a material transition. Ultra short pulse (UKP) lasers with picosecond or femtosecond pulses are often used for this purpose, as they offer high repetition rates and low pulse energy. For example, an optimal laser plate drilling process requires the complete removal of the insulator material, but the laser must be stopped when the copper layer is reached. In this case, the plasma signal can be used for process control as well as for quality monitoring and documentation. RAPID-LIBS performs this task on a pulse-by-pulse basis with real-time evaluation at a repetition rate of up to 1 MHz.

Inline process control for printed circuit board manufacturing

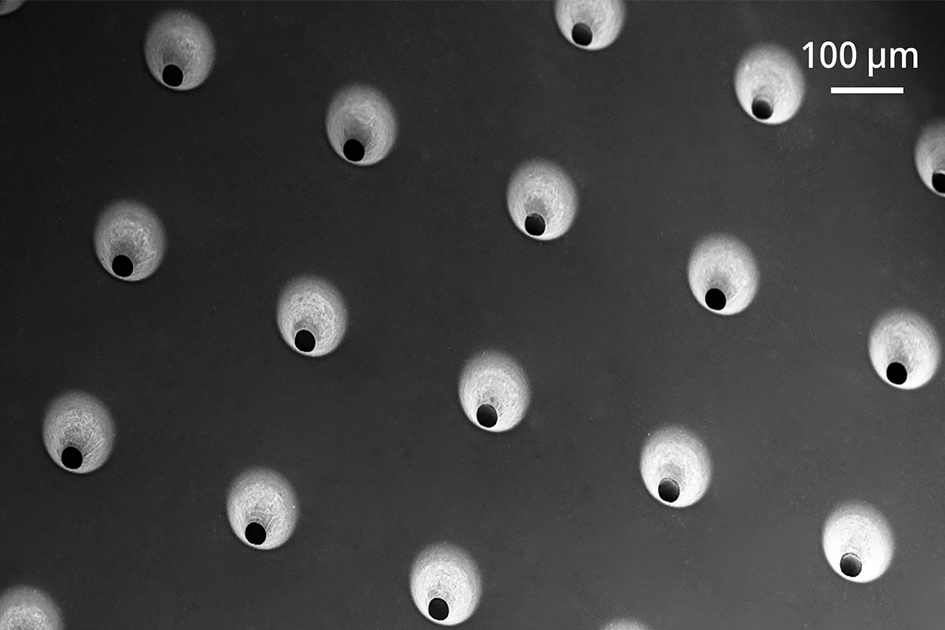

Printed circuit boards consist of a layer of copper foil applied to an insulating material made of a mixture of glass fiber and epoxy resin. To establish contact between the upper and lower sides, a UKP laser drills numerous 100-µm holes into high-density printed circuit boards in a matter of seconds. During this process, the laser removes the top layer of copper and the underlying insulating material. However, due to variations in material thickness, insulating material may remain in the holes, preventing a connection between the layers.

Because of the short cycle times, downstream inspection is often impossible or too costly. With RAPID-LIBS, however, each hole can be tracked pulse-resolved in real time. The sensor is integrated into the beam path and measures the radiation of the resulting plasma. The analysis of the plasma only takes a few nanoseconds and the results are sent back to the laser as feedback. As a result, safety margins can be reduced and cycle times increased. Additionally, the process enables complete quality documentation.