LiMo research project gets underway

Lithium mining in the Upper Rhine Valley: Measurement technology for the efficient extraction in geothermal power plants

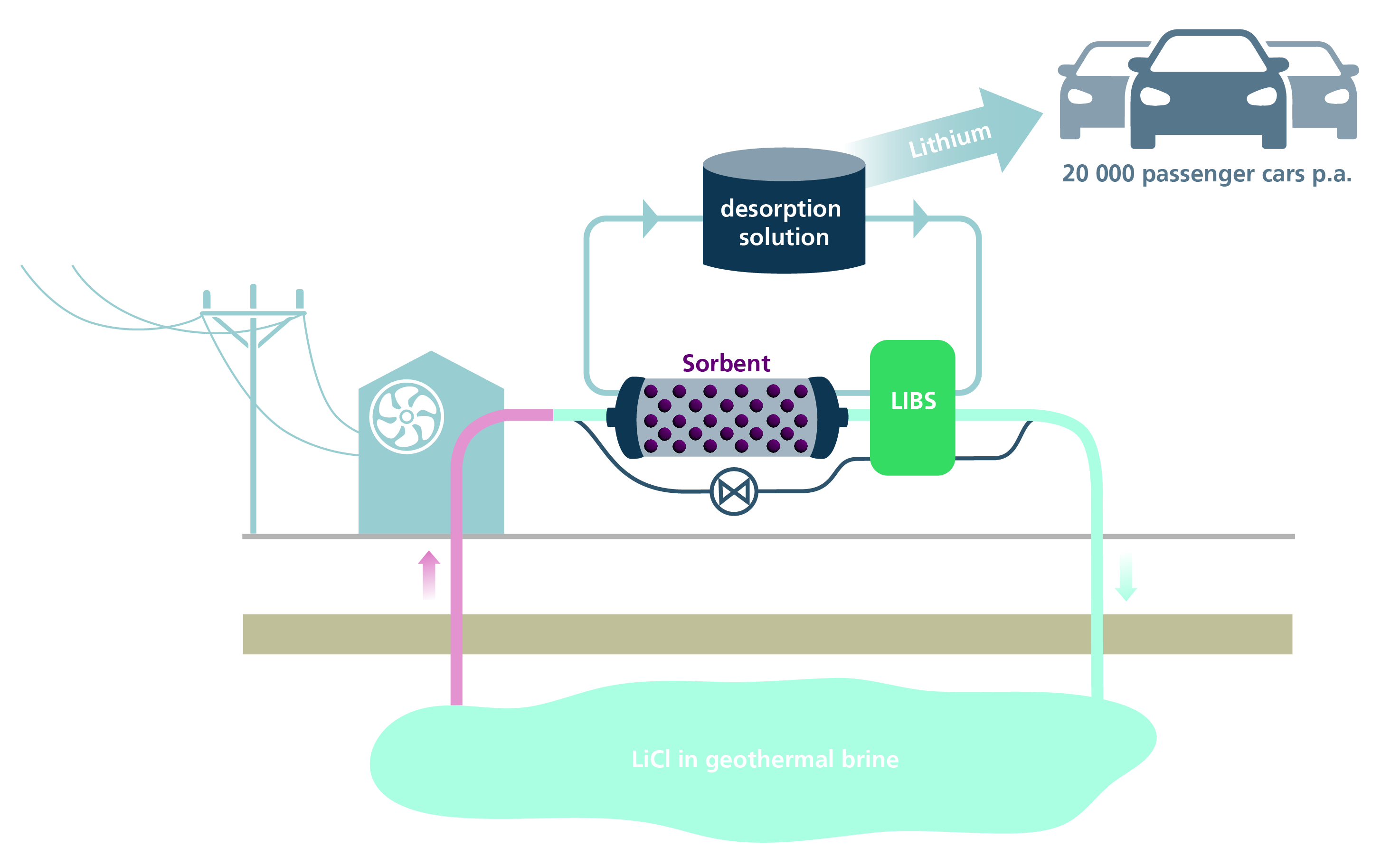

When it comes to the key raw material lithium, Germany almost exclusively relies on imports, even though the light metal is contained in geothermal brine. The departments of Geochemistry & Economic Geology at the Karlsruhe Institute of Technology KIT are working on a method to extract lithium as a by-product of geothermal energy production. As part of the LiMo research project, Fraunhofer IPM is developing an optical sensor intended to make the extraction process more efficient.

The global demand for lithium is rising because the light metal is indispensable for battery production. Geothermal brine is a source of lithium that is hitherto untapped. Thermal waters from the depth of the Upper Rhine Rift and the North German Basin contain considerable amounts of lithium – enough to cover a large part of the current demand by the German automotive industry. Geothermal power plants in these two regions are already pumping up brine, just to return it into the ground once the heat has been used.

KIT has developed a method for extracting lithium using a sorption process in a geothermal plant. The brine is led through a reactor filled with a lithium-selective sorbent, thus binding the lithium. The sorption speed depends on a number of parameters, such as the composition of the thermal water, its pH value, its lithium concentration and the flow rate. Once the sorbent is saturated, the direction of flow is reversed and a desorption solution separates the lithium from the adsorber. For an efficient and viable lithium extraction, the time the direction of flow is reversed must be precisely controlled based on when the saturation limit of the adsorber is achieved. The saturation can be deduced from the lithium concentration downstream from the reactor, a measurement that until now has required cumbersome laboratory processes.

Inline measurement of lithium concentration enables process control

A team at Fraunhofer IPM is developing a novel method based on laser-induced breakdown spectroscopy (LIBS) for the inline monitoring of the lithium concentration downstream from the reactor in order to enable the control of the sorption and desorption process for the first time. LIBS is an established materials analysis method where a short pulse laser transfers a minute part of material into plasma for spectral analysis. The LiMo research project aims to refine the method, making it suitable for difficult conditions in liquid at 20 bar and 90 °C. The LIBS system is to be tested in a pilot plant at a geothermal site in real operation.

The potential is immense: Apart from extracting lithium from geothermal plants, the method can also be used to recycle lithium from old batteries. The project will test this use case, too.

Further informationen

The LiMo project (inline lithium monitoring for the efficient extraction and process control of lithium from geothermal brine and recycling material) is funded by the Ministry of Economic Affairs, Labor and Tourism of the federal state of Baden-Württemberg.

Project partners

- Karlsruhe Institut für Technologie (KIT), Institut of Applied Geoscience, Professorship for Geochemistry & Econcomic Geology (Coordinator)

- Fraunhofer Institute for Physical Measurement Techniques IPM

Project term

01/01/23 to 12/31/24