New opportunities in industrial production

Industry 4.0, the connection of the real world with the virtual world, is a great leap for industry. It creates entirely new opportunities such as extreme flexibility: production processes can be adjusted to customer requirements in real time, and reliability: by means of automated quality control or largely self-regulating maintenance and repair, to give some examples. This has a great impact on the production process.

New demands on modern production

Consider this: Transferring sample specimens to a central measuring room and waiting (often for hours) for the batch to be released no longer meets the requirements of modern production. The problem is that the methods established in measuring rooms cannot easily be converted into a smart system and transferred to the production line. If in the past, one in one thousand components was submitted to a tactile check for certain geometric features using just one coordinate measuring machine, applying the same technology to in-process inspection would require dozens or more coordinate measuring machines. For a start, there usually wouldn't be enough space, not to mention that it would not be cost-efficient.

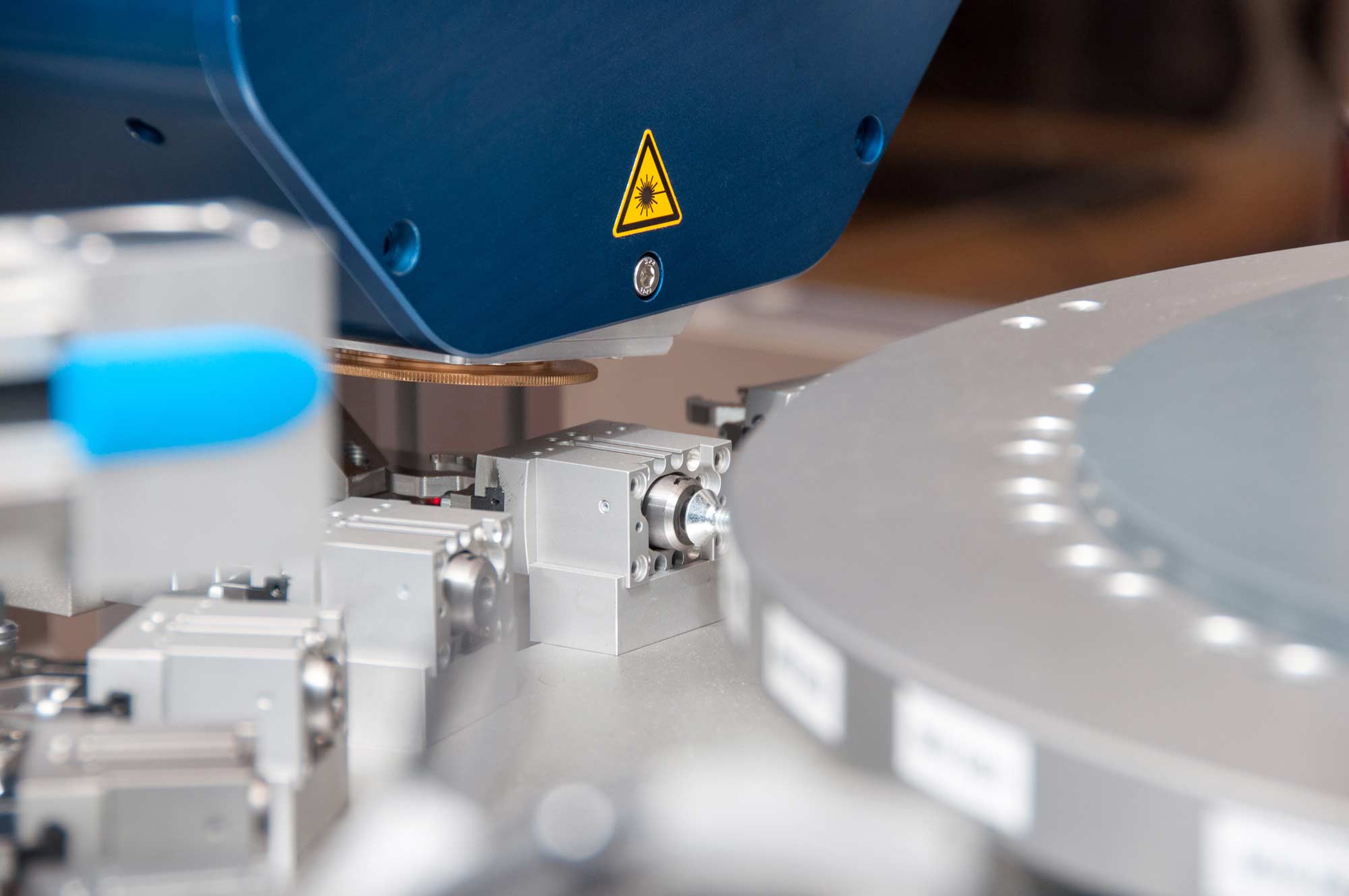

Optical measurement technology for speed and contactless processes

New measurement and test procedures are needed to enable flexible, inline-capable, 100 percent reliable production control. Processes using optical measurement technology have the advantage of being fast and contactless. Every day, we work on overcoming the disadvantages of this new technology compared with the established methods – and successfully so.

Thus, Fraunhofer IPM’s digital holographic 3D measurement systems are now able to achieve the same measuring accuracy as the world’s best coordinate measurement systems. And what’s more, the optical system records hundreds of millions of 3D points in the time in which a coordinate measuring machine would record one measuring point. This means the production process can benefit from an unprecedented volume of data in real time.

Data is the basis of the transformation

The data recorded by our sensors is the basis of the transformation towards a sustainable Industry 4.0. The speed of data recording and processing as well as the quality of the measurement data ensures that the product quality is consistently high.