LiMo-Praxis research project launched

Innovative measurement technology for efficient lithium extraction

Direct Lithium Extraction (DLE) is more environmentally friendly than traditional extraction methods and unlocks new resources. In the recently launched LiMo-Praxis research project, Fraunhofer IPM and the Karlsruhe Institute of Technology (KIT) are developing an optical method for real-time monitoring of lithium content in liquids for commercial lithium extraction.

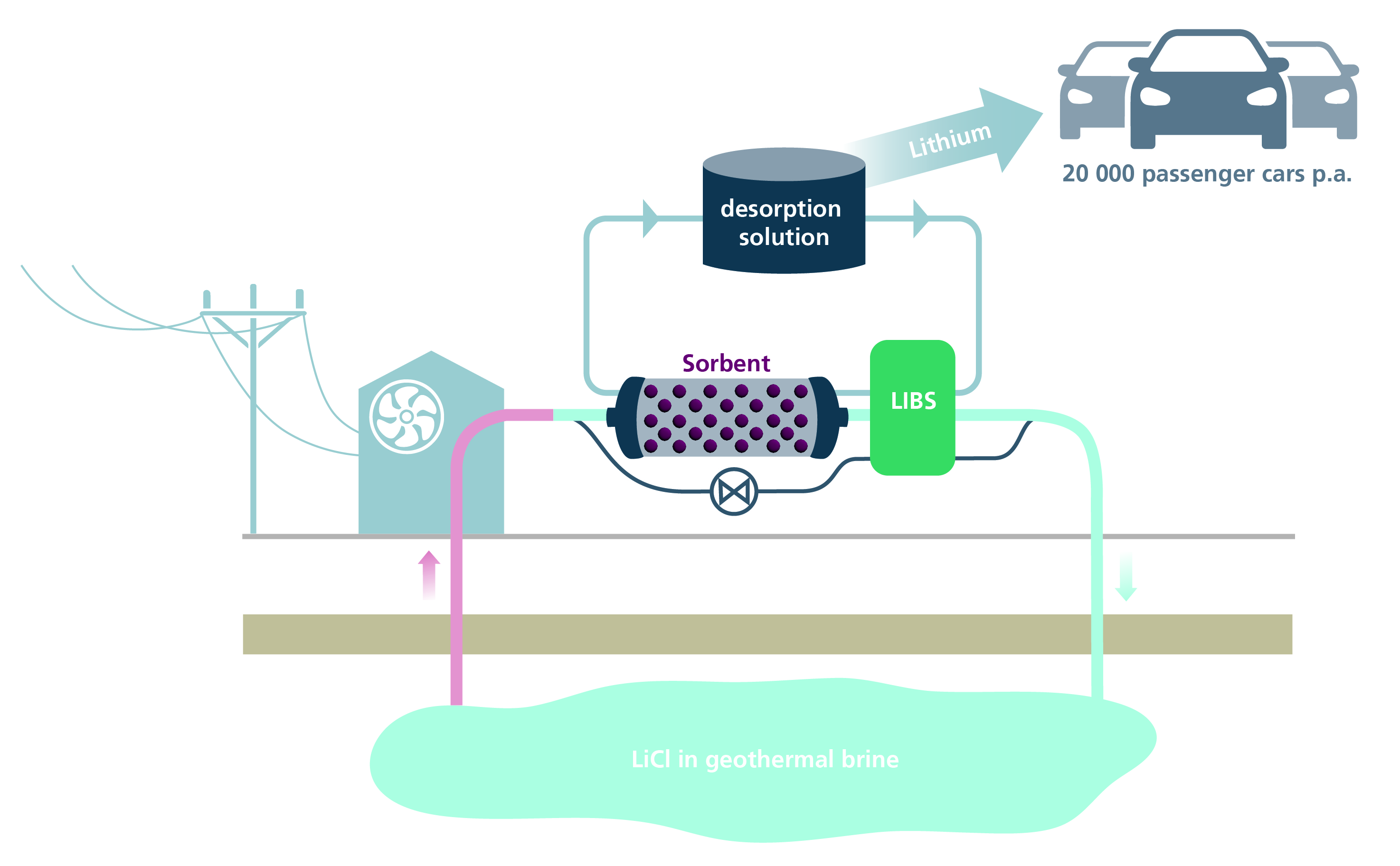

Lithium-ion batteries are a key component of the energy transition. The global battery production is expected to grow by 30 percent annually until 2030. However, traditional lithium extraction in South America, which involves evaporating lithium-containing brines in large basins, poses a serious threat to the environment and local freshwater reserves. Direct Lithium Extraction (DLE) from near-surface brines or deep geothermal sources offers a more environmentally friendly alternative that minimizes water consumption and accesses new resources in Europe.

Inline measurement technology for direct lithium extraction

A lack of commercially viable real-time monitoring methods of lithium content currently prevents the economic extraction of lithium using DLE. Following the successful completion of the LiMo project, in which lithium measurement was carried out under real DLE conditions for the first time, the Fraunhofer Institute for Physical Measurement Techniques IPM and the Institute of Applied Geosciences at the Karlsruhe Institute of Technology (KIT) launched the LiMo-Praxis follow-up project in March 2025 to commercialize the process. The project is funded by the Baden-Württemberg Ministry of Economic Affairs, Labor, and Tourism as part of the “Invest BW - Praxissprints” program. Together, KIT and Fraunhofer IPM researchers have laid the foundation for LiMo-Praxis by optimizing sorbents, setting up test facilities and developing initial methods for precise process control. Now, a pilot plant for testing under real conditions needs to be build.

Great potential – for lithium extraction and battery recycling

The measurement method is based on Laser-Induced Breakdown Spectroscopy (LIBS) and has the potential to significantly improve the efficiency and cost-effectiveness of lithium extraction using DLE, to minimize losses and contamination, and thus to increase the purity of the extracted raw material. To achieve these improvements, further chemical elements such as sodium, calcium, potassium, and magnesium must be quantified in sorption and desorption solutions. Furthermore, robustness against fluctuating process parameters such as pressure and temperature must be increased and measurement times reduced to less than one minute.

If the adjustments are successful, the innovative measurement technology can not only be used in classic lithium extraction, but also in battery recycling and geothermal energy. This opens up the possibility to access alternative lithium sources in Europe. Potential customers include plant manufacturers and operators of lithium extraction in salt flats, geothermal power plants, and recycling facilities.

Further information

LiMo-Praxis project

In the LiMo-Praxis project, researchers are working on the development of a monitoring method for the commercial extraction of lithium from aqueous solutions through Direct Lithium Extraction (DLE). The project is funded by the Ministry of Economic Affairs, Labor, and Tourism as part of the "Invest BW – Praxissprints" program.

Project duration

17.03.2025 – 16.10.2025

Project partners

- Karlsruhe Institute of Technology (KIT), Institute of Applied Geosciences (AGW), Department of Geochemistry & Economic Geology

- Fraunhofer Institute for Physical Measurement Techniques IPM