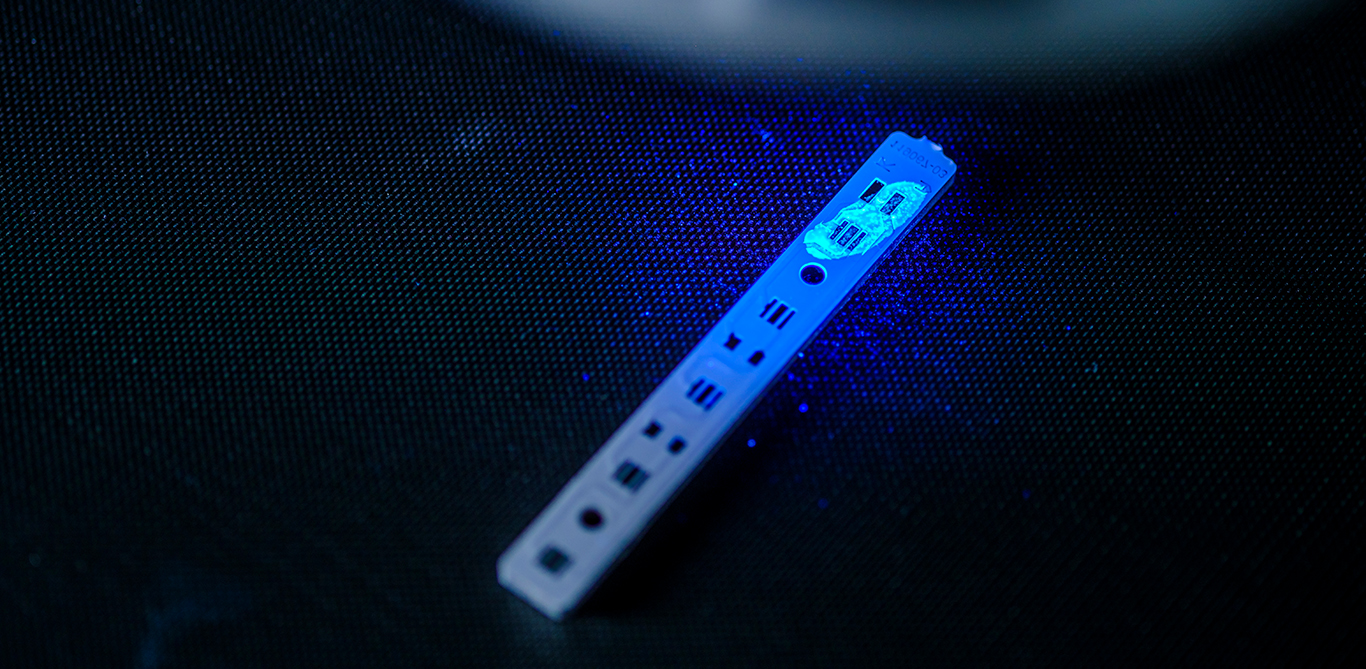

Contact-free – precise – rapid

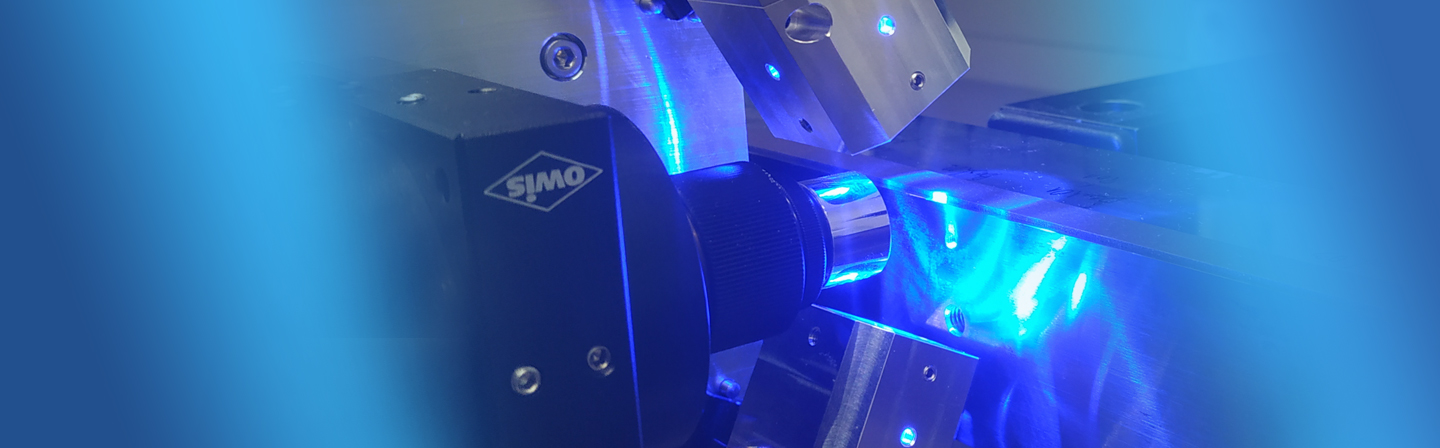

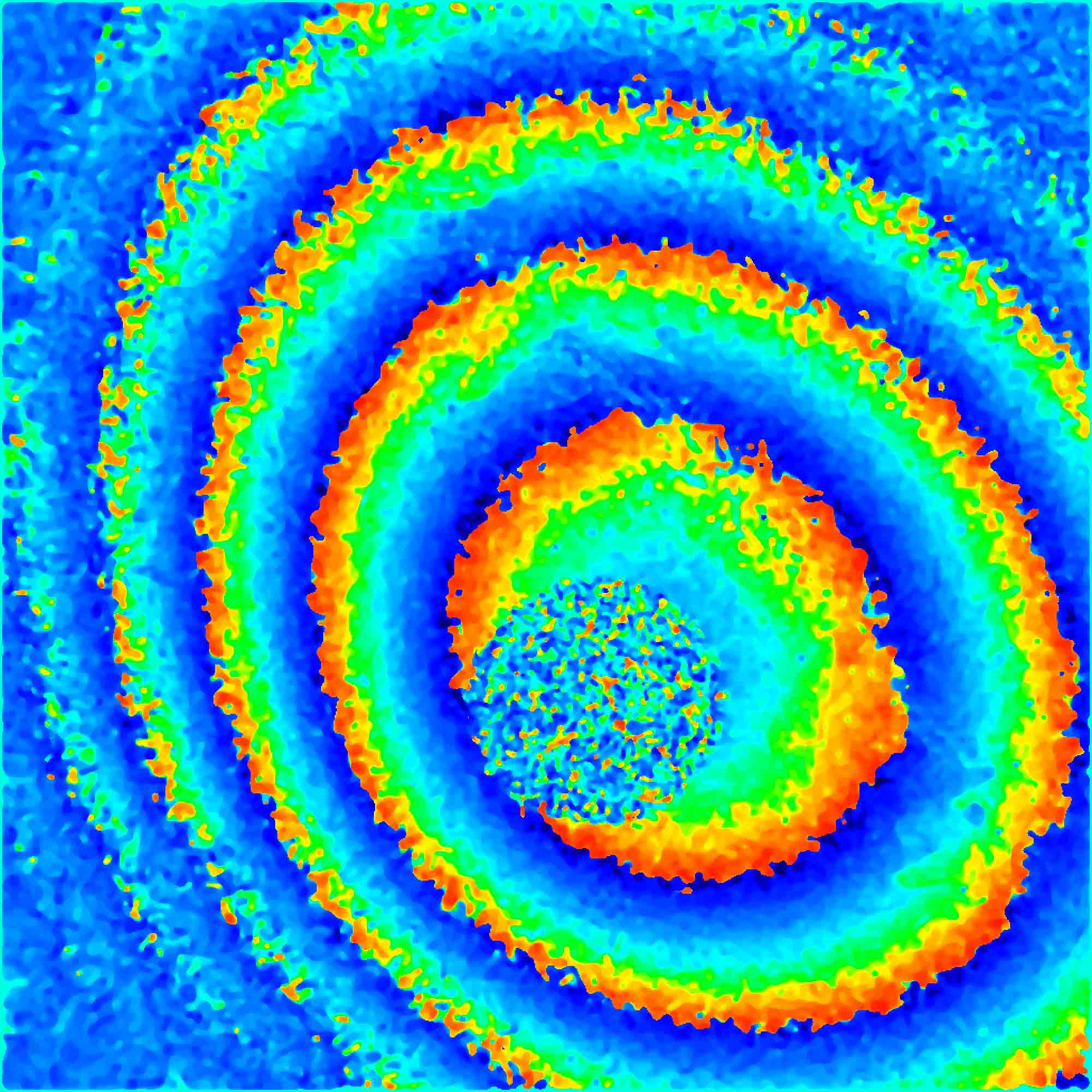

Fraunhofer IPM has been developing turn-key optical measurement technology for industry and research partners for over 30 years now. »Measuring, monitoring, optimizing« – this is the guiding principle for our production control systems. Our inline measurement techniques and optical surface analytics focus on the interplay of optics, mechanics, electronics and software. We create systems that are fast, sensitive and at the same time robust enough for a permanent use under production conditions.