Traceability is the cornerstone of Industry 4.0, ensuring sustainable manufacturing and perfect documentation. Only if individual components and semi-finished products are definitively identified can data collected in the production process be traced back to individual components.

Our Track & Trace Fingerprint technology is the first of its kind to use existing surface microstructures as distinguishing features for tracing mass-produced components. Each component is assigned a unique bit sequence – or fingerprint (FP) – based on its own individual microstructure, eliminating the need for any additional marking.

Successful integration into production lines

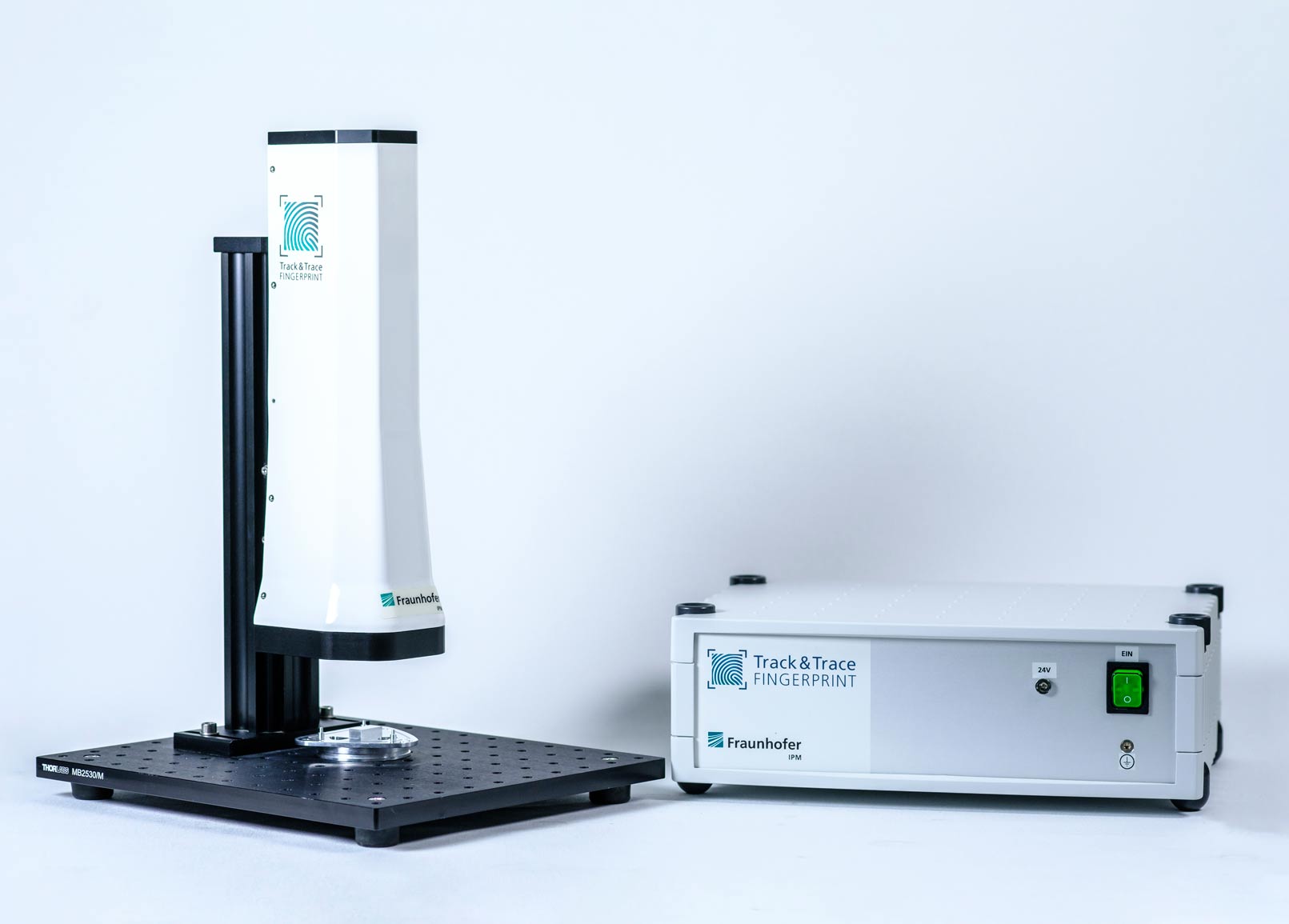

Track & Trace Fingerprint is already being used in industry for inline component tracing. Camera systems provide the images necessary to identify components in production. These systems are placed where important production parameters are set to be assigned to the individual components. A number of factors must be considered, including the mounting space, the handling systems, the rate of production, the environmental conditions, the amount of components in circulation and, of course, the component surface itself. All of these conditions can be tested using the Track & Trace Fingerprint test stand, making it an indispensable tool for the integration of component-tracing technology into the production line.

Planning marker-free tracing under production conditions

Nearly all technical surfaces have unique features that can be used for tracing purposes – similarly to a human fingerprint. These microstructures and the changes they undergo in production can be analyzed using the Track & Trace Fingerprint test stand. The camera system (FP reader) and software (FP laboratory software) parameters can be adjusted for optimal recognition results. For example, the type of lighting used by the FP reader as well as its aperture, depth of field, field of view and evaluation position can be adjusted according to each individual component. The resulting findings enable precise planning for later use in the production line.

Instruction and support in the commissioning process

The Track & Trace Fingerprint test stand makes it possible to set the constraints for using the Track & Trace Fingerprint technology for specific components and process steps as well as to determine the necessary handling accuracy. Only a few dozen components are needed to ensure a reliable result.

Fraunhofer IPM supports companies who want to use this technology in the commissioning process and provides detailed instruction to the employees. Track & Trace Test is available for purchase or rental. Based on the foundation of substantiated test results, Fraunhofer IPM works together with users to develop and integrate a complete system for enabling the marker-free tracing of components in the production process.