Fraunhofer IPM develops microscopy systems for specific measuring tasks. These fully automated systems provide fast and precise measurements and are used for inline production control. Our systems are sought whenever standard metrological applications fall short, for example in fast texture inspection or the inspection of large, flat surfaces for micrometer-sized defects and impurities.

Our microscopy systems check the fit of components with complex geometries with micrometer precision, one piece a second. We have also developed specialist microscopes for the fully automated and rapid surface inspection of continuous materials, such as technical tapes.

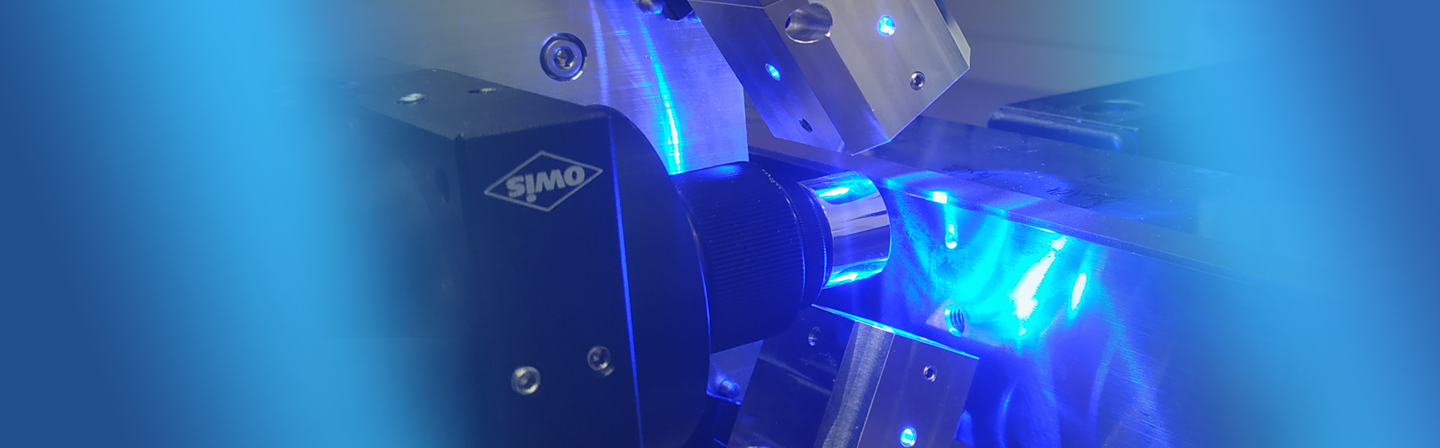

Inline-capable multi-camera systems for specialist applications

Our team is proficient in all standard microscopy methods as well as the optical simulation and design of optical systems. What’s more, we develop dedicated microscopy systems for measuring tasks that conventional microscopes cannot deliver. We often combine imaging sensors to create a multi-camera system that provides a comprehensive solution. We optimize lighting and lenses, mechanical and electrical interfaces as well as software to meet the specialist requirements of our customers, creating inline-capable systems suitable for their specific setups.

Quick analysis of large data volumes

Fraunhofer IPM offers dedicated software packages for data interpretation and sequential control including graphical user interfaces and standard communication interfaces. We continuously optimize the sophisticated image analysis algorithms that can be used to analyze texture and microscopic structures in real time. For example, our analysis algorithms enable the detection and classification of particles, the evaluation of the texture of surfaces, or chip inspection. If required, the algorithms can run on modern graphic cards to interpret extensive image data right away during the production process. For suitable scenarios, algorithms are based on machine learning methods.