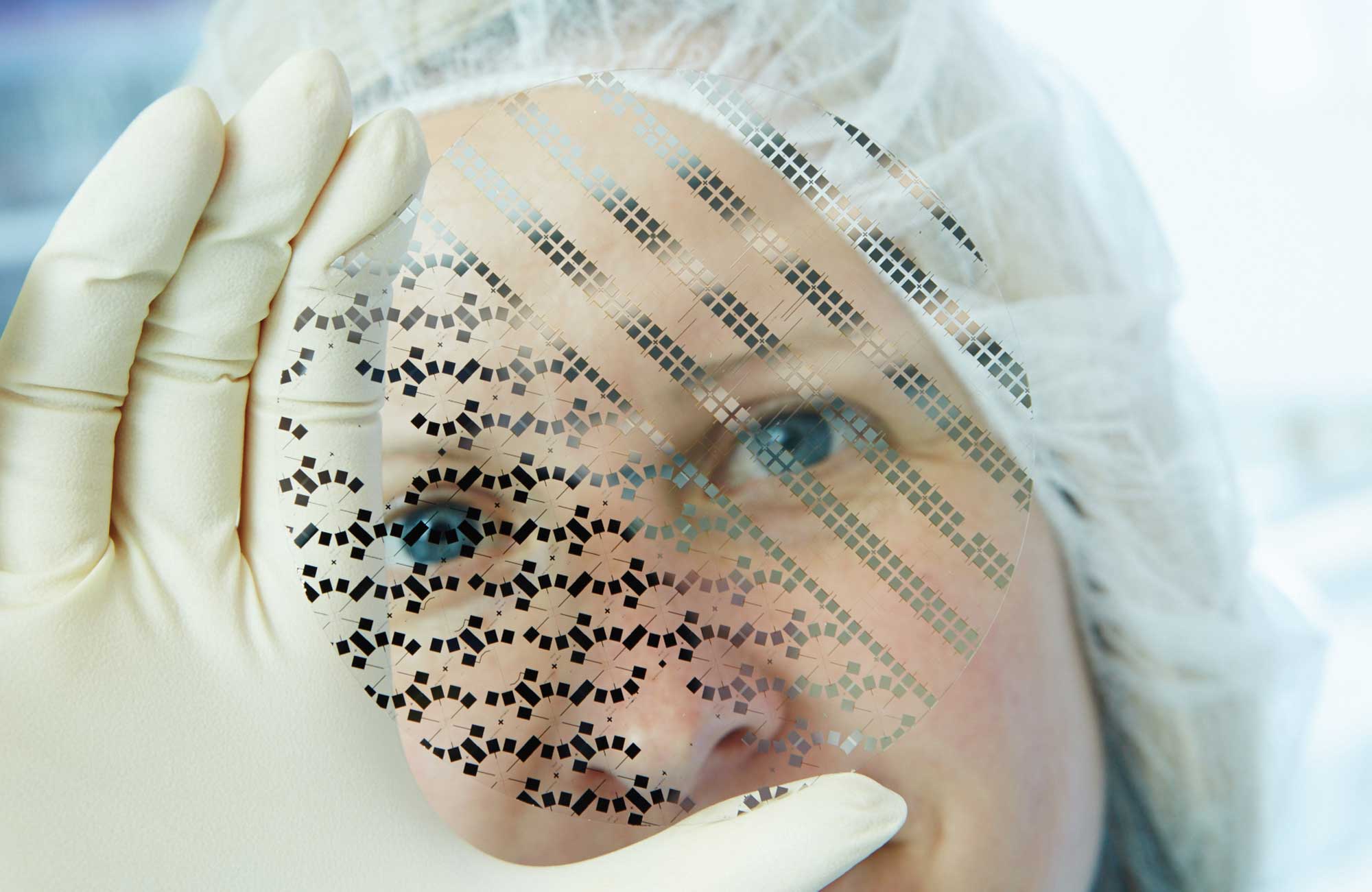

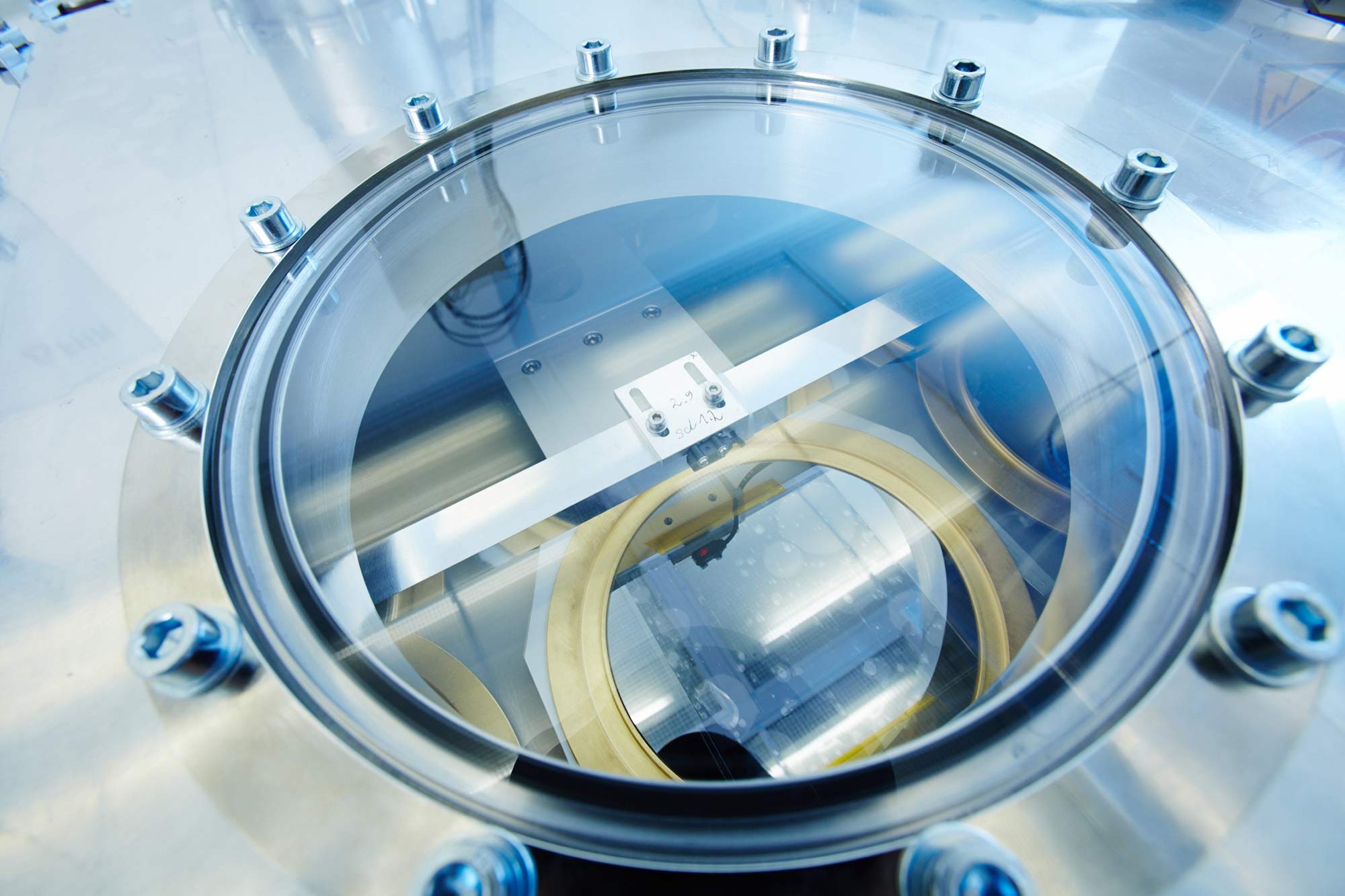

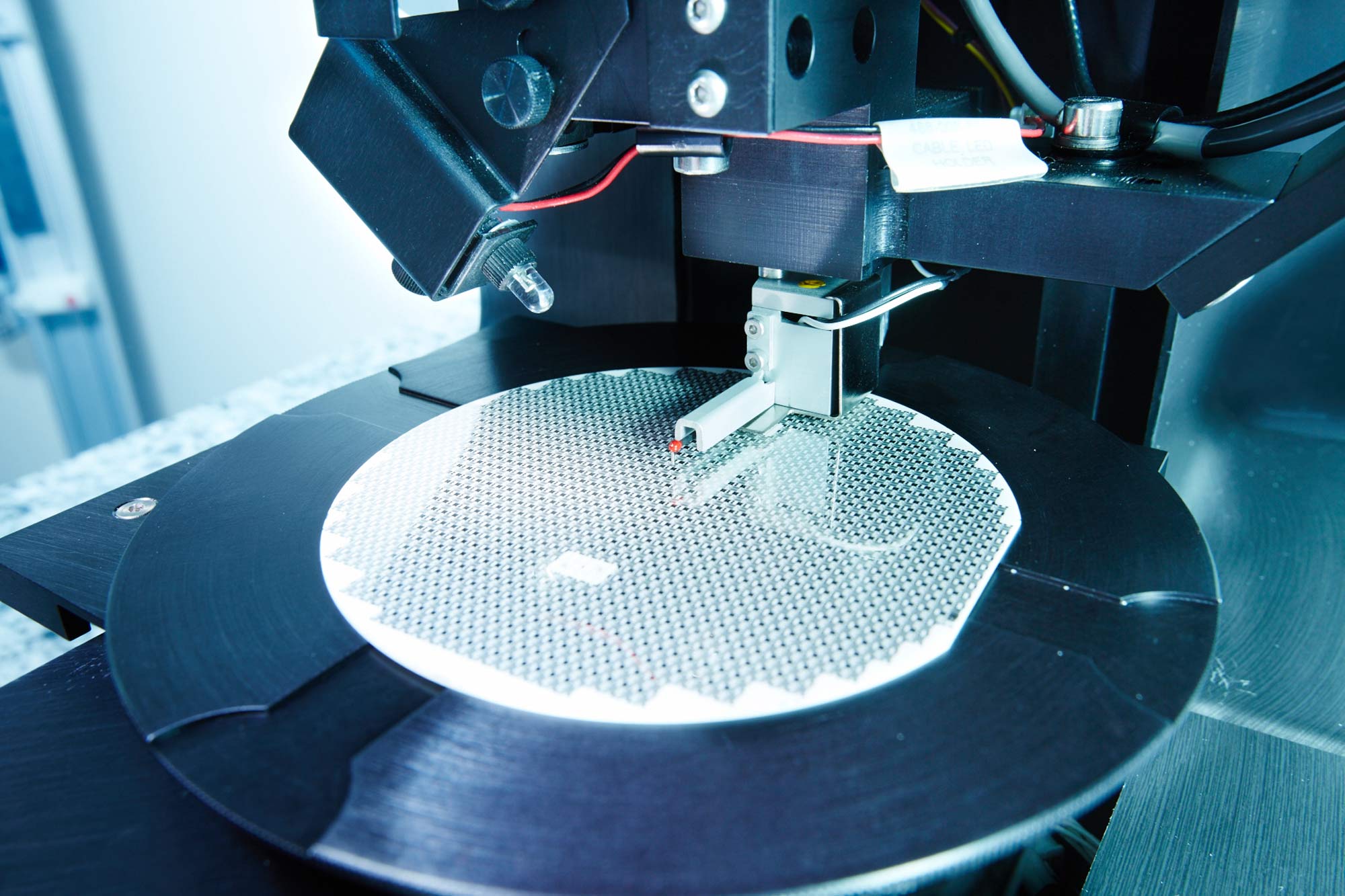

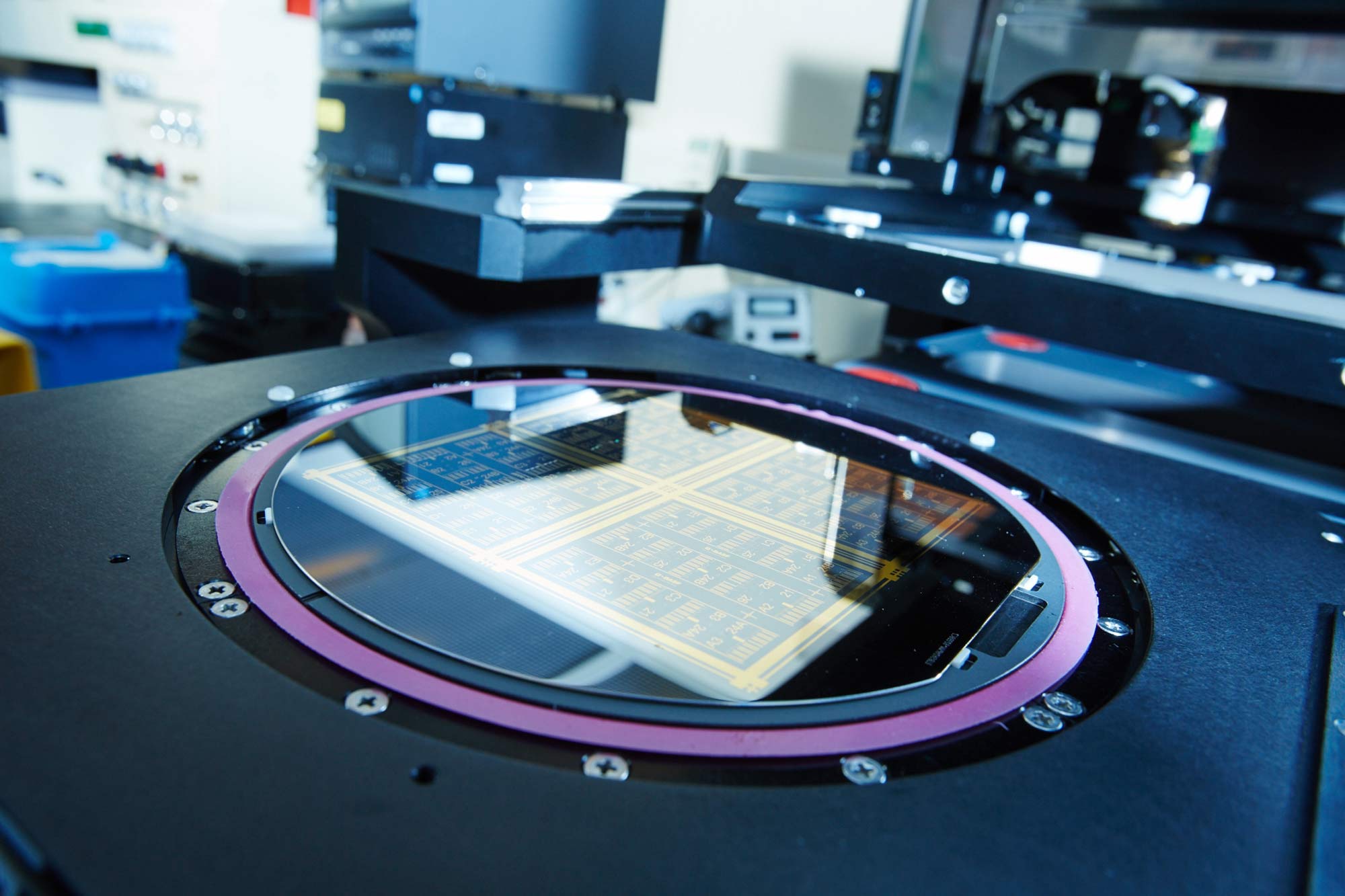

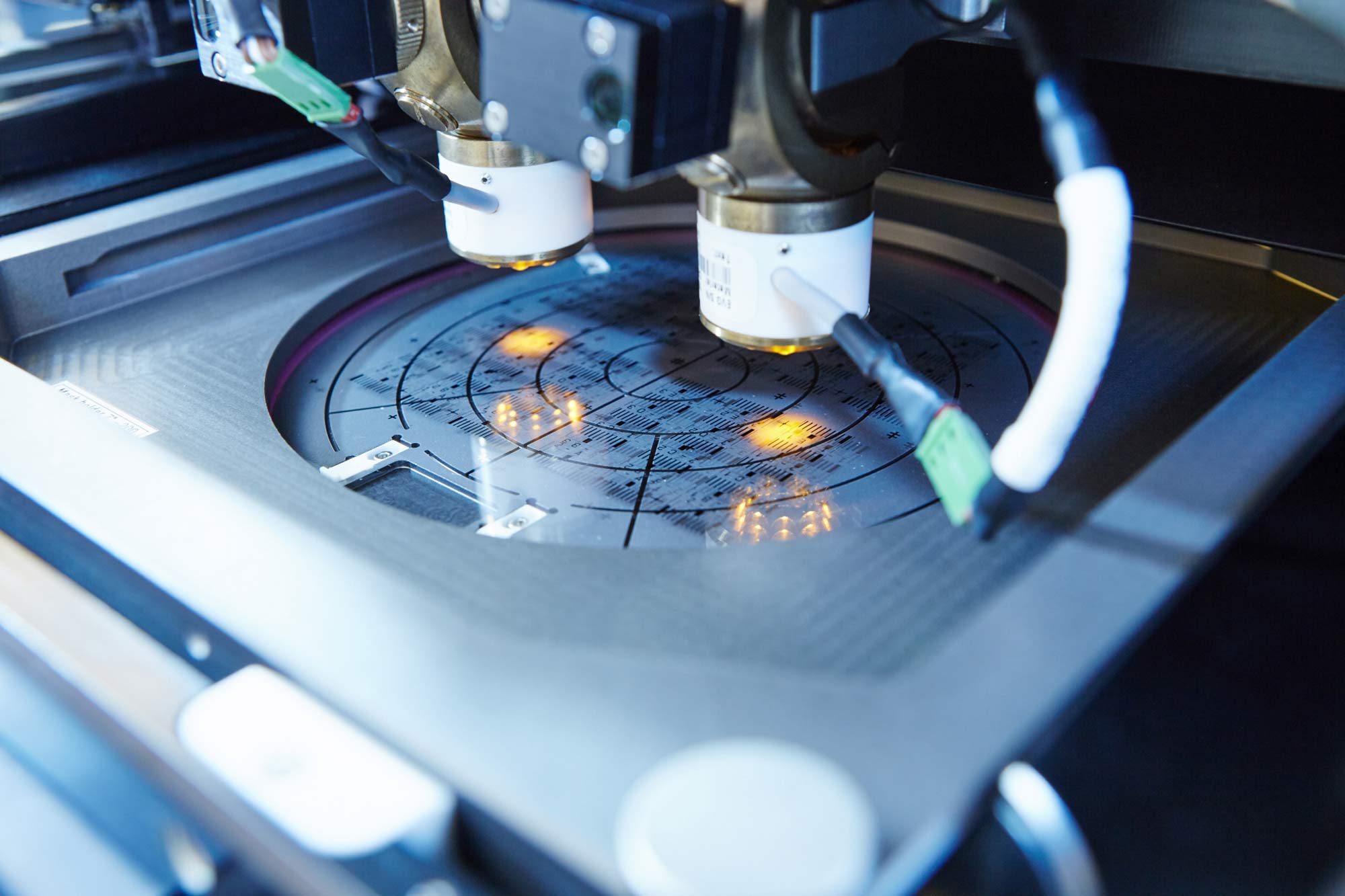

Fraunhofer IPM is equipped with a 400m² clean room of class 100 / ISO 5 with first class equipment. We model, coat and structure materials, from development to prototype production. Depending on your requirements, we advise you based on our long-time experience. With our procedures, we cover nearly the whole spectrum of microsystem technology.

- Design and simulation

- Substrate preparation/cleaning

- Structuring

- Coating/diffusion

- Construction and bonding technology

- Structural and materials analysis

Dealing with most different materials, as substrates and functional coatings, is daily routine for our employees. Substrates can be flexible foils, ceramics, glass, silicon or special optical materials of different geometry and size, circular or rectangular, as fragment or 6 inch wafer.

Use our clean room equipment and our know-how from science and daily research. Contact us, we will be delighted to help you!