Extremely compact and fast actuators based on shape-memory alloys

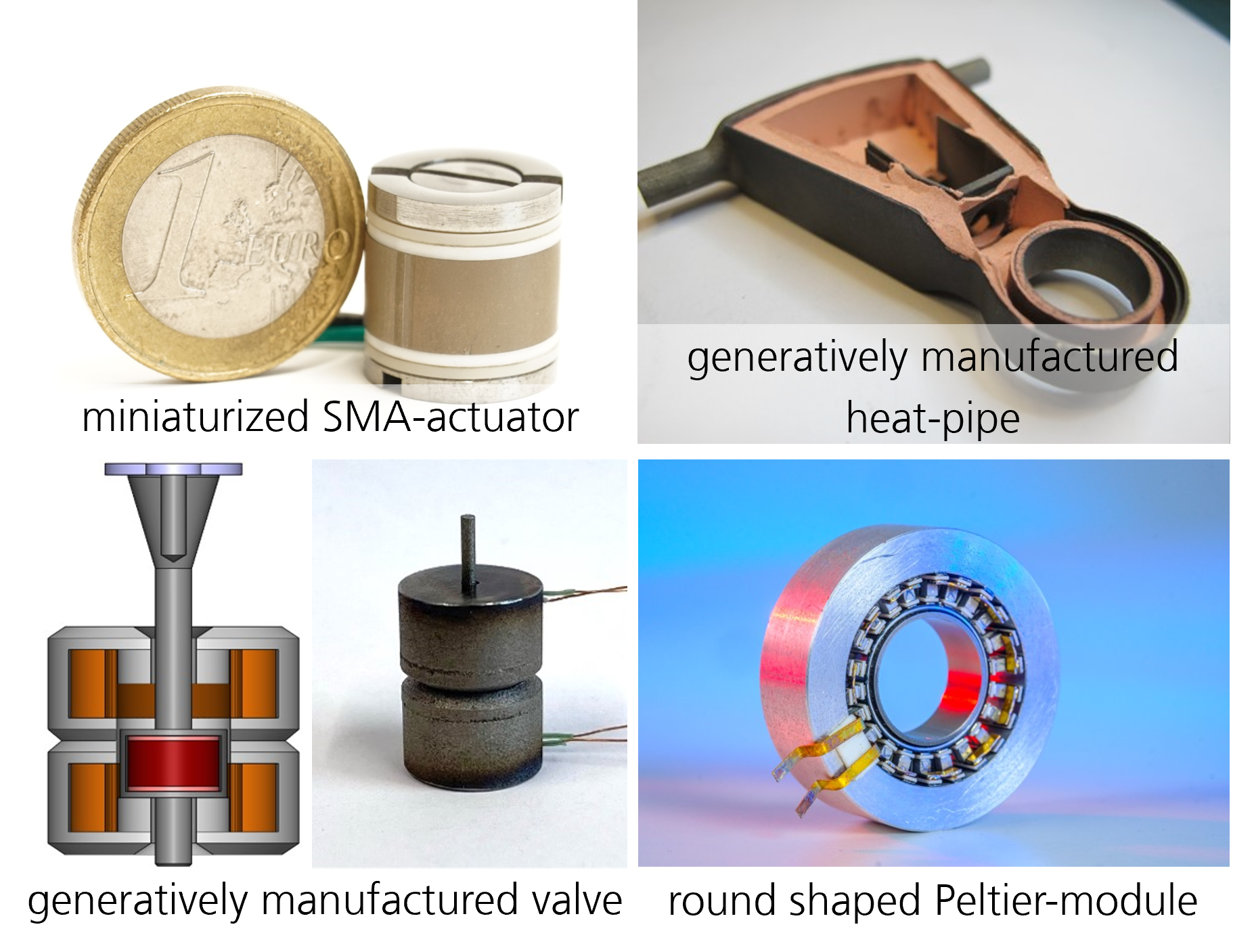

Actuators based on thermal shape memory alloys (SMA) boast the highest energy density of all actuators presently available. They are capable of generating high forces in a small space, and the structural change generated by temperature change can be used to switch the actuator. While heat in the actuator can be increased with little effort, quick cooling presents a particular challenge.

Various approaches for regulating the actuator temperature have been investigated by Fraunhofer IPM together with other Fraunhofer Institutes as part of the HochPerForm project. One option is cooling via latent heat – i.e., via evaporation and condensation of a fluid on the actuator surface – as used in heat pipes, for example. To prevent a continuous flow of heat from the actuator to the cold side, various switching mechanisms were examined and miniaturized valves were implemented in heat pipes.

Thermoelectrics offer another technical solution for regulating the actuator temperature. The Peltier effect allows heat to be pumped from one side of a so-called Peltier module to the other. Arranged in a ring around the actuator, such a tubular Peltier module controls both the heating and cooling of the actuator. The advantages of this system include its very compact design, precise regulation of the actuator temperature, and simple control via two electrical cables. This temperature regulation solution forms the basis for actuator systems that combine extremely high energy density with switching frequencies of more than one hertz in a minimum of space.