Miniaturized photoacoustic gas sensor for detecting refrigerants and carbon dioxide

Photoacoustic gas detection – basically

The principle of photoacoustic detection has become widely accepted in recent years thanks to cost-effective and powerful LEDs and thermal IR emitters. Photoacoustic sensors show low base noise since an acoustic signal is only generated when the target gas is present. Currently, the most common type of photoacoustic sensors are based on MEMS microphones, which convert the acoustic signal into an electrical signal.

However, dependence on microphone manufacturers has several disadvantages that impede the development of reliable photoacoustic sensors for the mass market. Every company has its own microphone designs, which makes it difficult to achieve a uniform circuit board layout and makes changing manufacturers costly. In addition, global supply chains are prone to problems, and the quality of microphones can vary significantly. This is why a more reliable technology for converting acoustic signals into electrical signals is needed.

Microflow instead of microphone

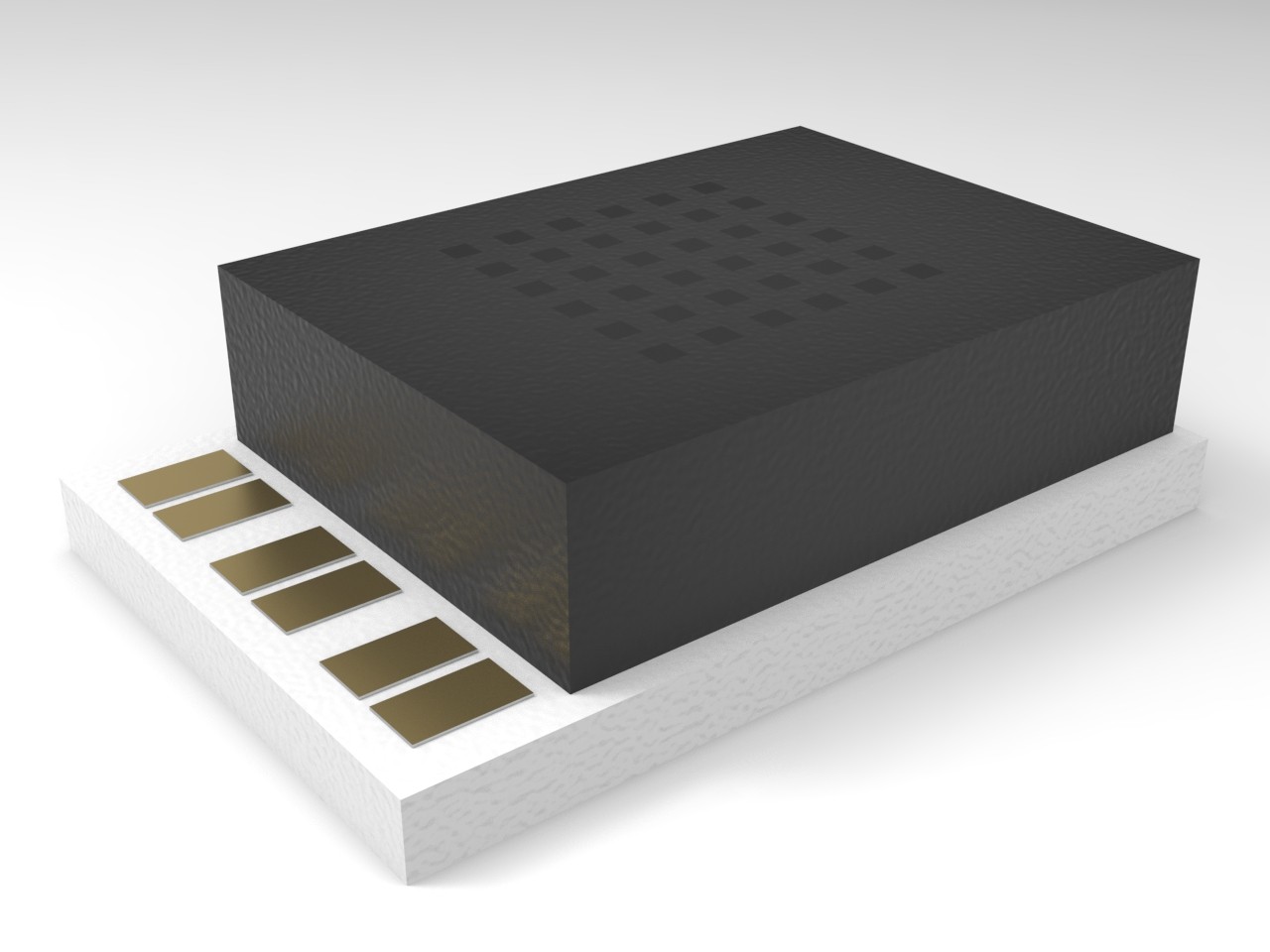

In the MiniGas joint project, Fraunhofer IPM is working with industrial partners to develop a novel sensor that uses the measuring principle of flow sensors to detect small acoustic waves. A MEMS-based platinum heating structure is controlled to a fixed heating capacity. If the photoacoustic effect causes a pressure wave, the heating structure cools down due to the flowing medium. The cooling directly indicates the intensity of the sound wave. The amplitude of the sound wave is directly dependent on the amount of light absorbed and thus on the concentration of the target gas.

The innovative use of the photoacoustic effect thus enables the development of a highly sensitive miniaturized sensor that does not require the use of microphones.

The gas sensor is intended for use in medicine (breath gas analysis), energy and environmental technology (monitoring indoor air quality), and in vehicles (detection of refrigerants in air conditioning systems).