Inline particle measurement technology

SPOT research project kicks off

Particulate contamination and defects on component surfaces are detected during production either through visual inspection or by rinsing the component and analyzing the rinsing fluid. This type of quality control is state of the art, but it is cumbersome and cannot be integrated into the manufacturing process. As part of the SPOT research project, Fraunhofer IPM is working together with partners to develop a novel optical inline measurement system.

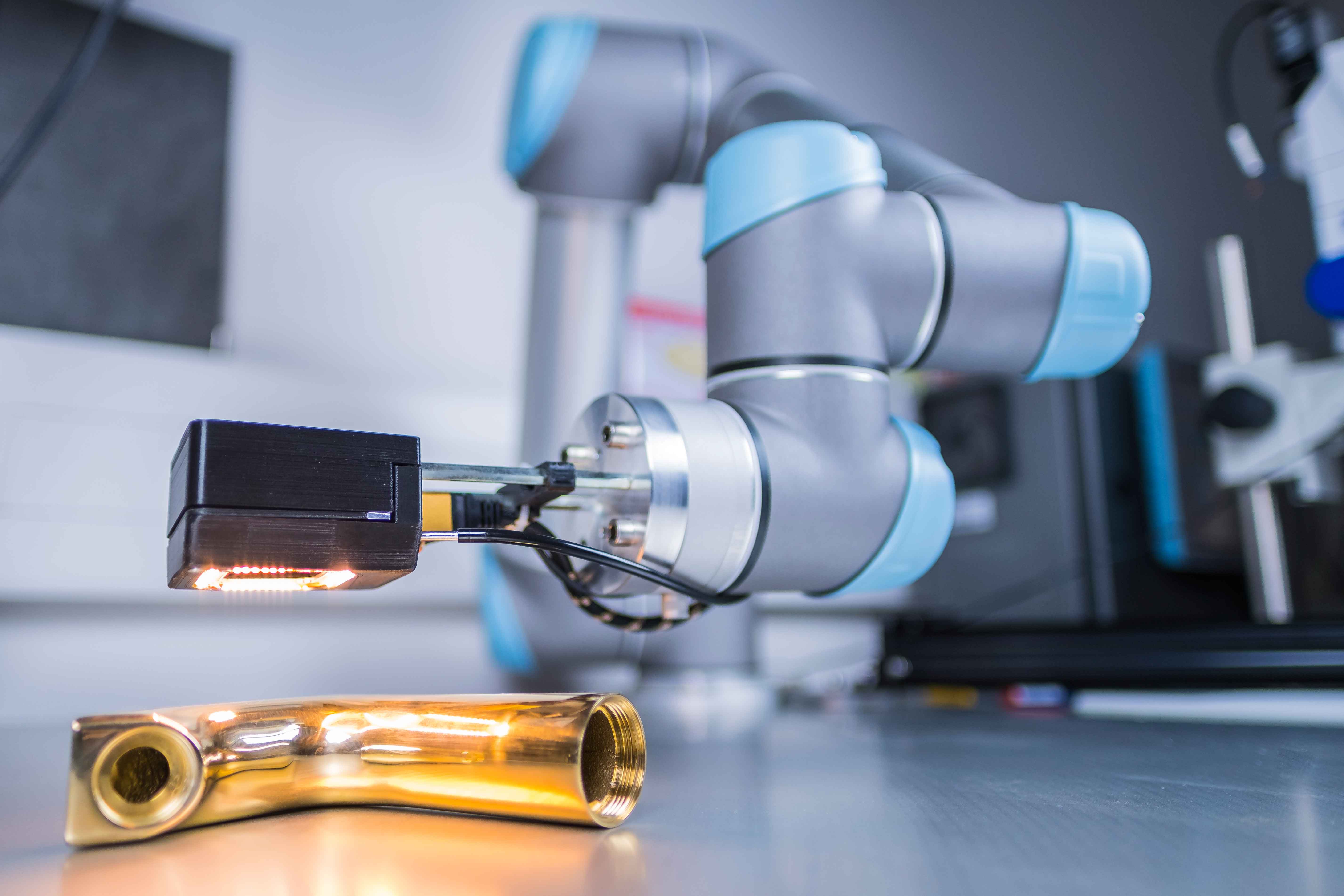

In manufacturing components, conformance to defined cleanliness limit values is essential. The detection and classification of particles on component surfaces should be done in the production line. This way, any necessary corrections to the production process can be done within the production cycle. This includes optimizing the parameters of a cleaning system and removal of a part out of the process. Fraunhofer IPM and its partners in the SPOT research project began working on the development of the necessary technologies in April 2021. The envisaged solution consists of three parts. The first part is an optical sensor for fully inspecting component surfaces for defects and particles immediately after cleaning. The second part comprises cleaning systems for the qualified cleaning of complex components. The third and final part is an Artificial Intelligence (AI) based control system that analyzes the cleaning and measurement system and adjusts it to suit the individual components and the affiliated testing requirements as autonomously as possible.

SPOT – detection and classification aided by AI-based image analysis

The objective of SPOT is to enable the detection and classification of particulate contamination and defects on component surfaces using adaptive photonic surface testing with adaptive image analysis. Optical images will be generated with the assistance of adaptive light field control and automatically analyzed using AI technology. The adaptive light field will allow for optimal lighting selection for each component surface, ensuring that defects and particles on the component can be safely inspected irrespective of its geometry or reflective property.

![BMBF_CMYK_Gef_M [Konvertiert]](/en/press-publications/press-releases/particle-measurement-SPOT-research-project/jcr:content/contentPar/sectioncomponent/sectionParsys/textwithasset/imageComponent/image.img.jpg/1630134967271/BMBF-gefoerdert-2017-en.jpg)