Materials, components, and systems are exposed to sometimes harsh environmental conditions throughout their life cycle. Varying temperatures and pressures, as well as certain gases, affect the quality and service life of products. This needs to be taken into account already during product development. HALT (highly accelerated life test) or HASS (highly accelerated stress screen) tests simulate the long-term influence of environmental factors within a very short period of time. This allows potential flaws to be identified and eliminated already during the development phase.

As early as 1889, Svante August Arrhenius, later winner of the Nobel Prize, discovered that temperature has a decisive influence on the rate of chemical reactions. This doubles when the temperature is increased by just 10 K. It is precisely this correlation that can be used for accelerated aging tests.

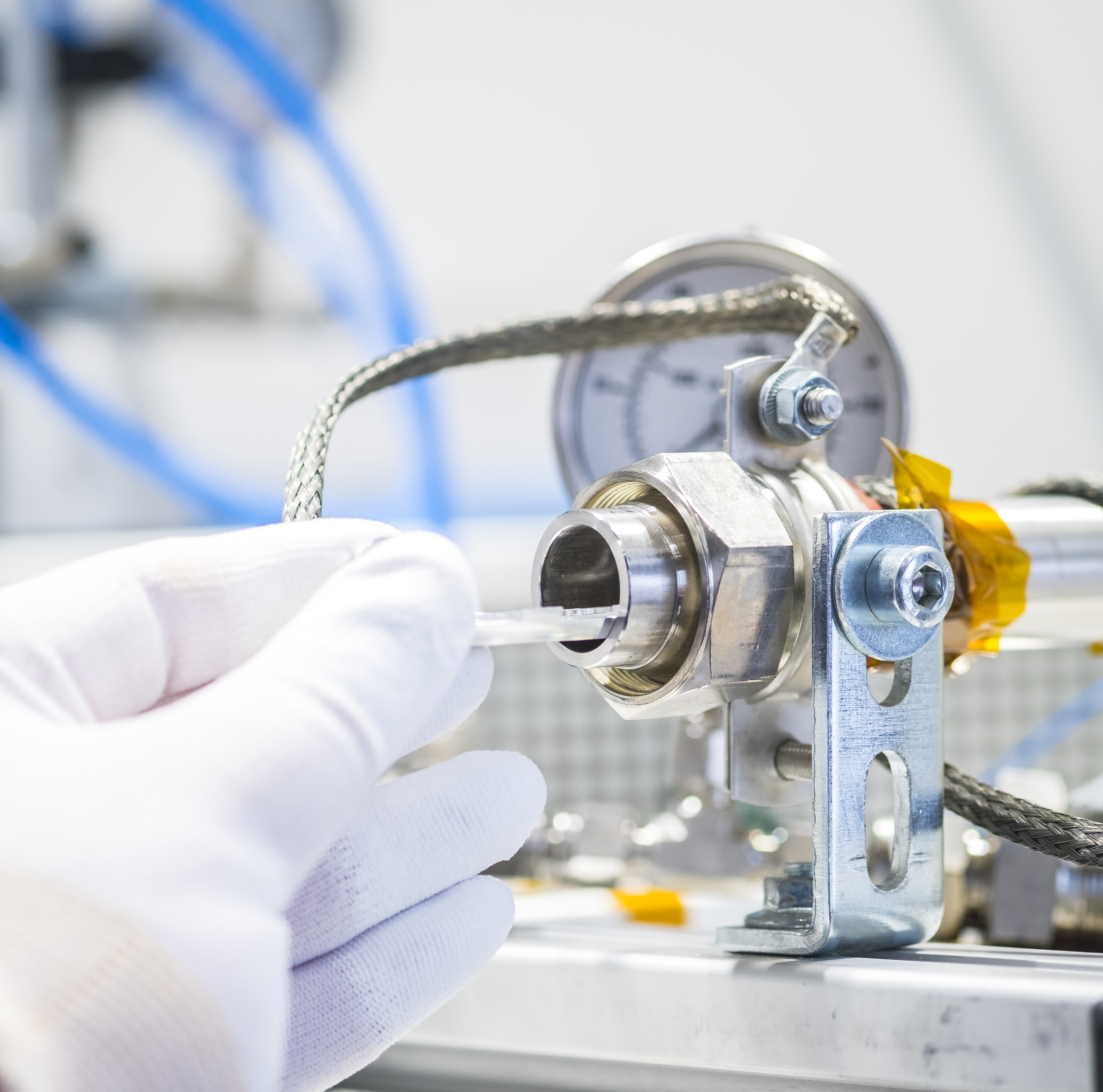

In our test facilities, we expose materials, components, and also complete sensors and measuring systems to precisely defined conditions in order to simulate accelerated aging. This includes high temperatures as well as specific atmospheres with up to 100 percent hydrogen content and a pressure of 200 bar. We use various material analysis and imaging techniques to investigate the effects of accelerated aging processes.