Design and simulation

- Simulators: Finite element model (FEM) with COMSOL and mathematical studies with MathLab

- Layout tools: CAD / CleWin or ProEngineer

Substrate preparation / Substrate cleaning

- Plasma systems: O2 , CF4

- Polishing machine for chemical-mechanical polishing procedures (CMP)

- Chemical cleaning baths: Si, glass, optical materials

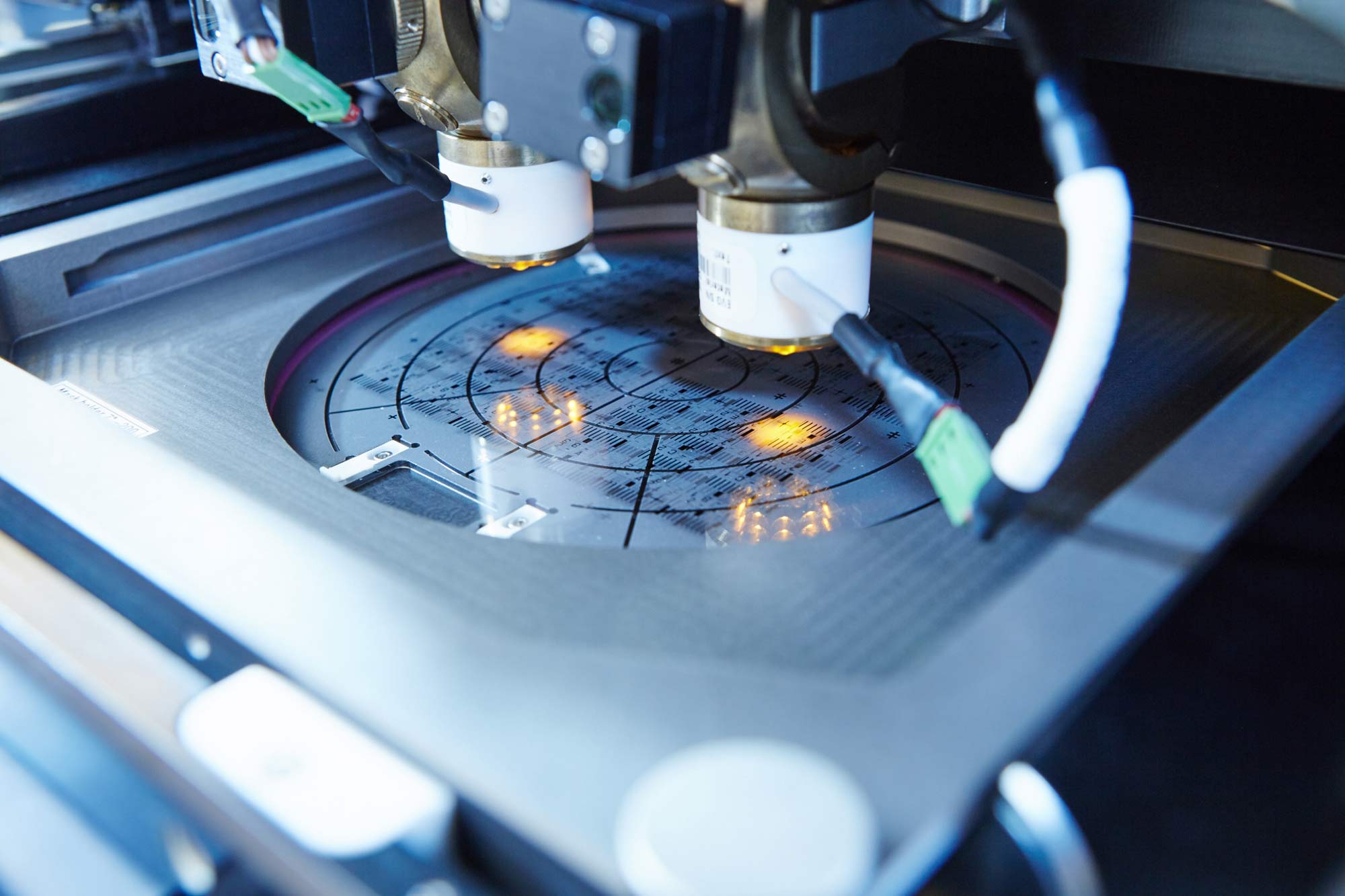

Structuring

- Photolithography: 365 nm exposure in proximity and vacuum contact, back exposure, DUV-flood exposure, Spin-/ Gyrset-Coater, Puddle developing

- Nanoimprint-Lithography (NIL)

- Selective wet chemical etching technique

- Dry etching processes: Reactive Ion Etching (RIE) , Kryo Inductively Coupled Plasma (ICP)

Materials synthesis

- Melt synthesis

- Powder production and processing

Coating / Diffusion

- Sputter systems: co-sputter systems, substrate heating up to 400°C

- Evaporation systems: electron-beam evaporator and thermal evaporator

- Material-/ inkjet printing

- Electroplating

- Diffusion and oxidation plants: dry and wet oxidation, temperature up to 1200°C

- Pulsed laser deposition (PLD)

Mounting and assembling technology

- Precision saw / wafer saw

- Ball / wedge bonders

- Welding unit: Resistance-, Wolfram-Inertgas (WIG) and ultrasonic welding

Structure and materials analysis

- Ellipsometry

- Profilometry

- Scanning electron microscope (SEM) with energy dispersive X-ray spectroscopy (EDX) and electron backscatter diffraction (EBSD)

- Computed Tomography (CT) with micro- and nanofocus

- Laser scanning microscope

- Measurement technology for the determination of thermoelectrical, optical and gas sensitive characteristics