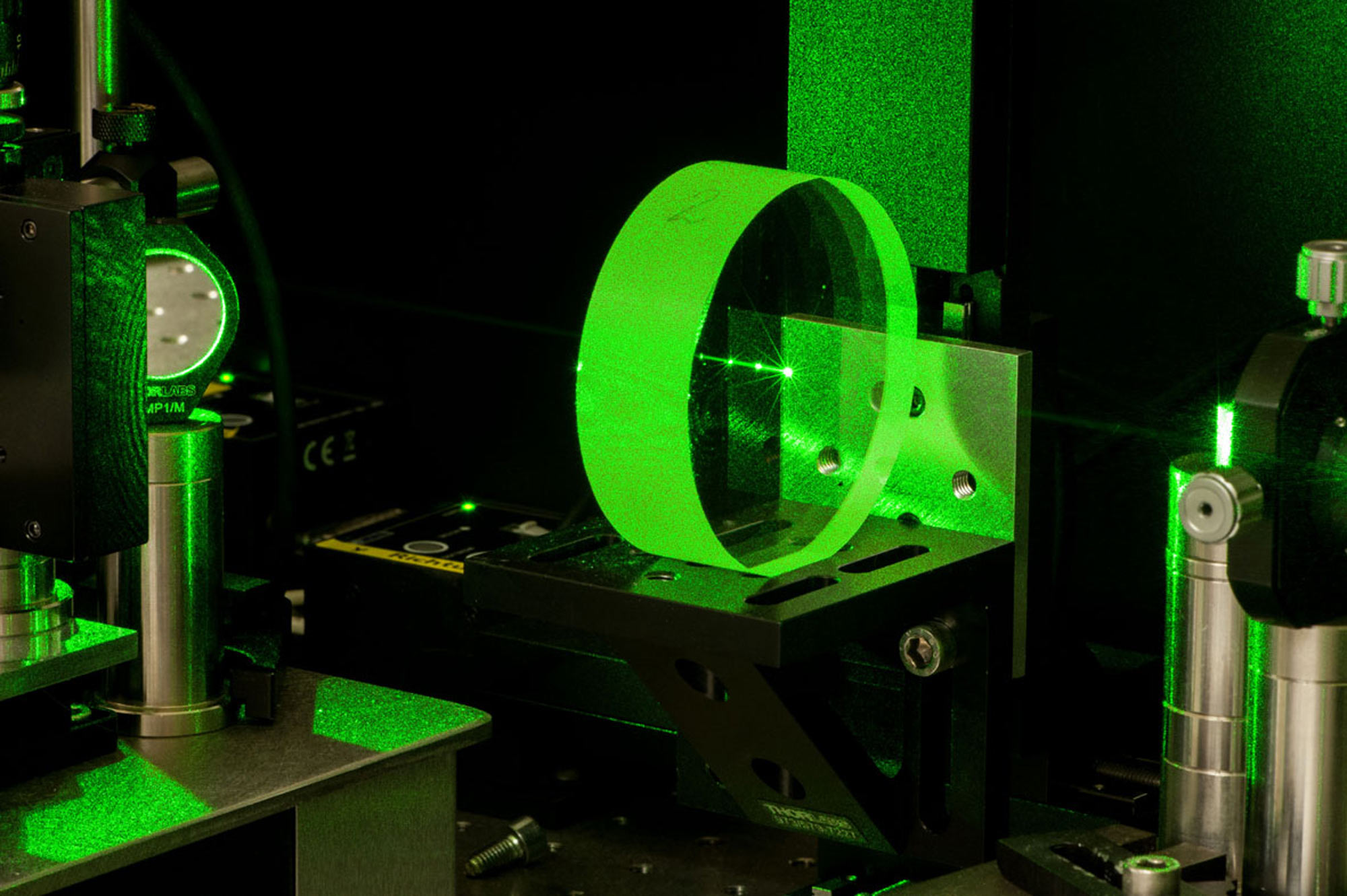

Fraunhofer IPM offers service measurements to determine residual absorption in volume materials and dielectric coatings with ppm sensitivity. With this we support you both in technology development in material production and in the quality control of optical components, especially for use with high-power lasers.

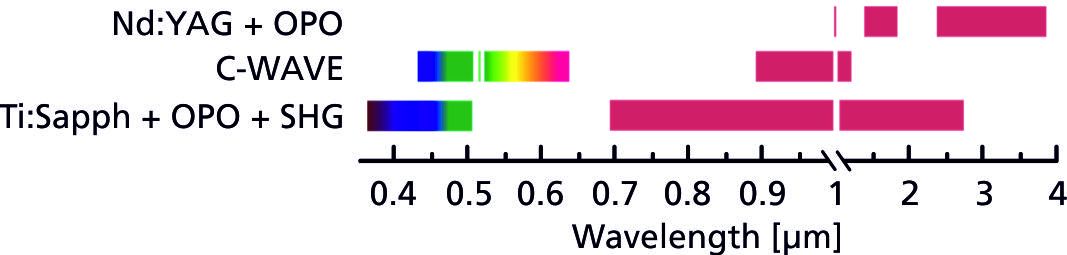

Depending on the material and wavelength, our measurement stations can detect residual absorptions in the range of a few ppm/cm in volume materials and down to less than 1 ppm in coatings. The IPM measurement technique is unique in that it facilitates the recording of absorption spectra from the visible spectral range to the mid infrared even beyond the standard laser wavelengths by using tunable optical parametric oscillators as pump light sources.

For developers of optical materials and coatings, spectroscopic investigation of residual absorption can help optimize manufacturing processes. In quality control, this allows the examination of optical components at customer-specific wavelengths.

The tunability of the pump sources is also used for the calibration of the absorption data – making it possible to access absorption measurements on »new« materials.