Higher measuring accuracy thanks to new materials

Thermopiles are electrical components that convert infrared radiation directly into electrical energy via the so-called Seebeck effect (also known as the thermoelectric effect). A temperature-dependent voltage is generated at the junction point of two electrically conductive materials if the temperature at this point differs from the ambient temperature.

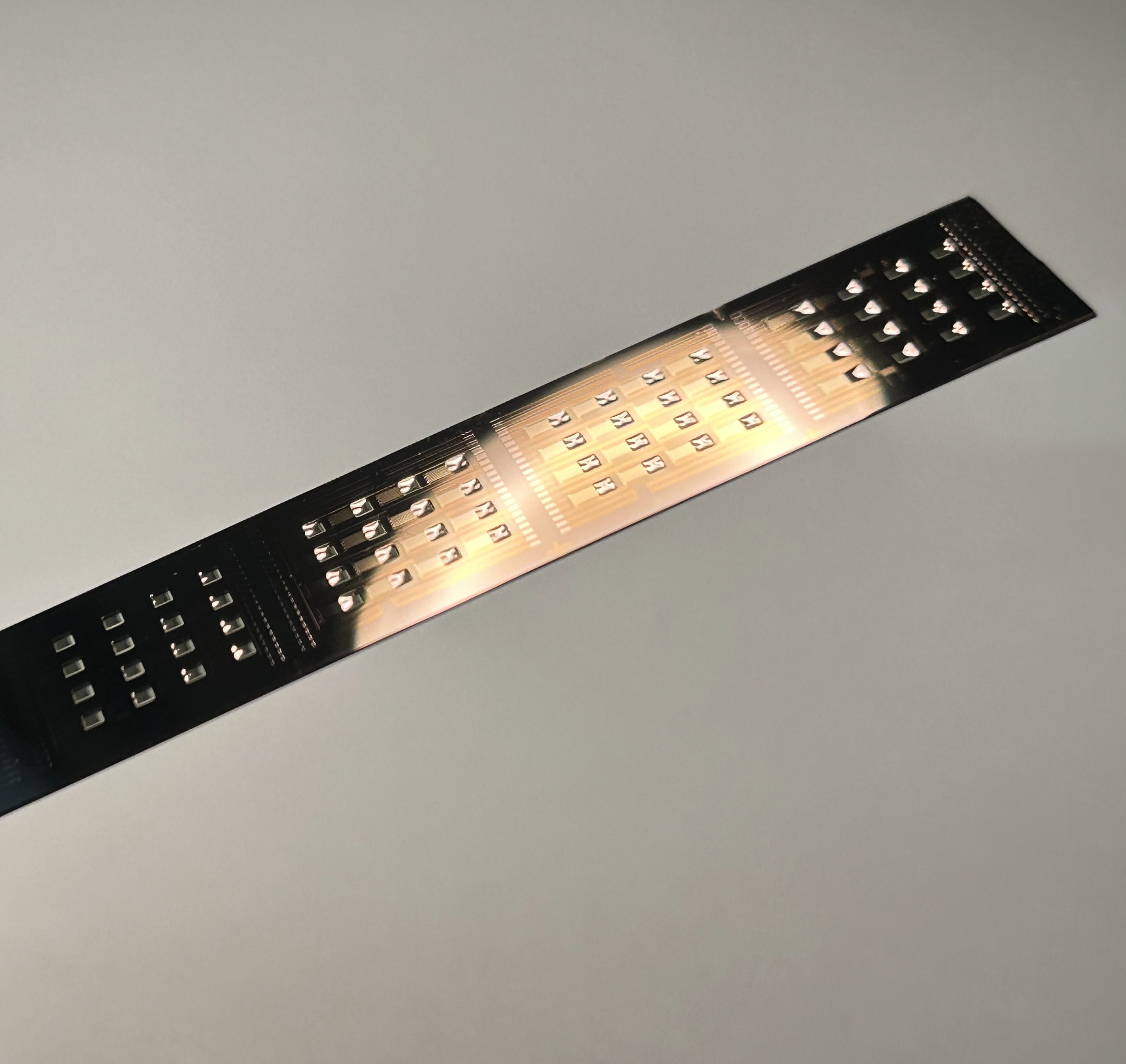

At Fraunhofer IPM, we are developing thermopiles based on novel materials that detect temperatures more sensitively and accurately than existing thermopiles. To this end, we rely on bismuth telluride (Bi2Te3), a material that features a particularly high thermoelectric figure of merit at room temperature. With a targeted combination of design and materials, we optimize the sensitivity of thermopiles and measure temperatures with significantly higher accuracy. This makes thermopiles interesting for use in thermal radiation detectors, calorimeter structures or heat flow sensors, for example.

Thermal simulations and specifically equipped laboratories enable optimal material development

During development, we conduct thermal simulations. This allows us to calculate the efficiency and thermal coupling of the thermopiles and optimize their component geometry prior to implementation – which significantly reduces development times.

In specifically equipped laboratories, we develop processes for the deposition and microstructuring of highly efficient thermoelectric materials such as bismuth telluride or bismuth antimonide. Furthermore, we are developing thermopile structures with optimized IR absorber layers on thin membranes in order to detect thermal radiation and temperatures dynamically and with spatial resolution.

In our laboratories, we dispose of a large number of qualified measurement methods which we utilize to precisely determine the material and thermal properties of the developed sensors.