A way out of manual inspection

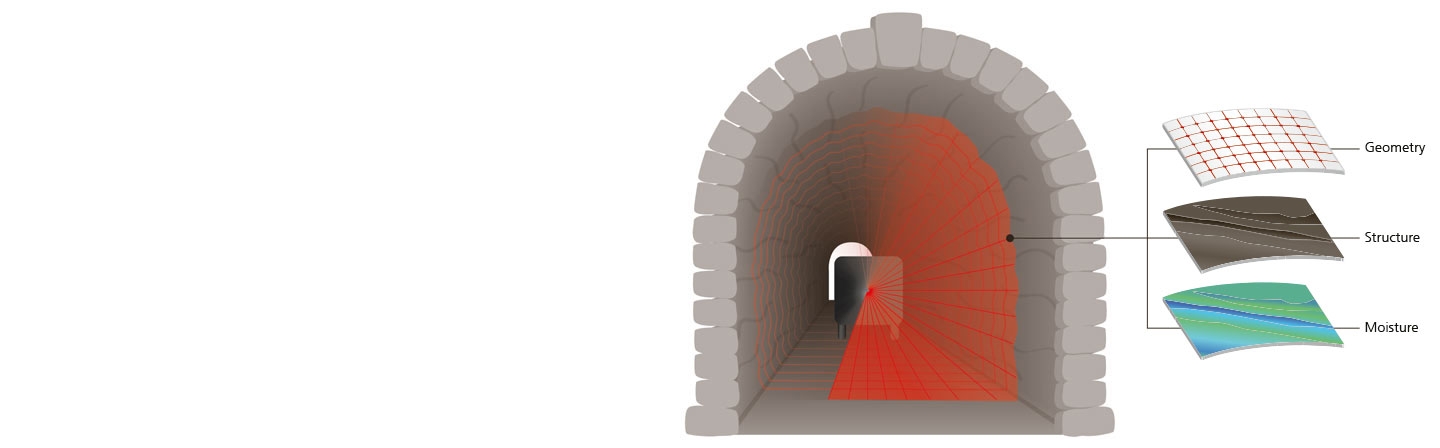

Modern transport infrastructure would be inconceivable without tunnels. In Germany, there are hundreds of road, rail and underground tunnels requiring regular maintenance. Many of these tunnels have been in operation for decades, so regular maintenance and repair are becoming increasingly important in order to avoid safety risks and consequential damage. Today, inspections are largely performed manually in a slow, costly and unobjective process, while the degree of digitization is low. The inspections are lengthy, expensive and do not provide any objective condition data. In the near future, however, Building Information Modeling (BIM) will also become the standard in tunneling requiring complete digitalization of the building information. Fraunhofer IPM develops technical measurement solutions for a cost- and time-efficient inspection process during regular operation.