From the laboratory into the process: sensitive and selective measurement of gases and liquids

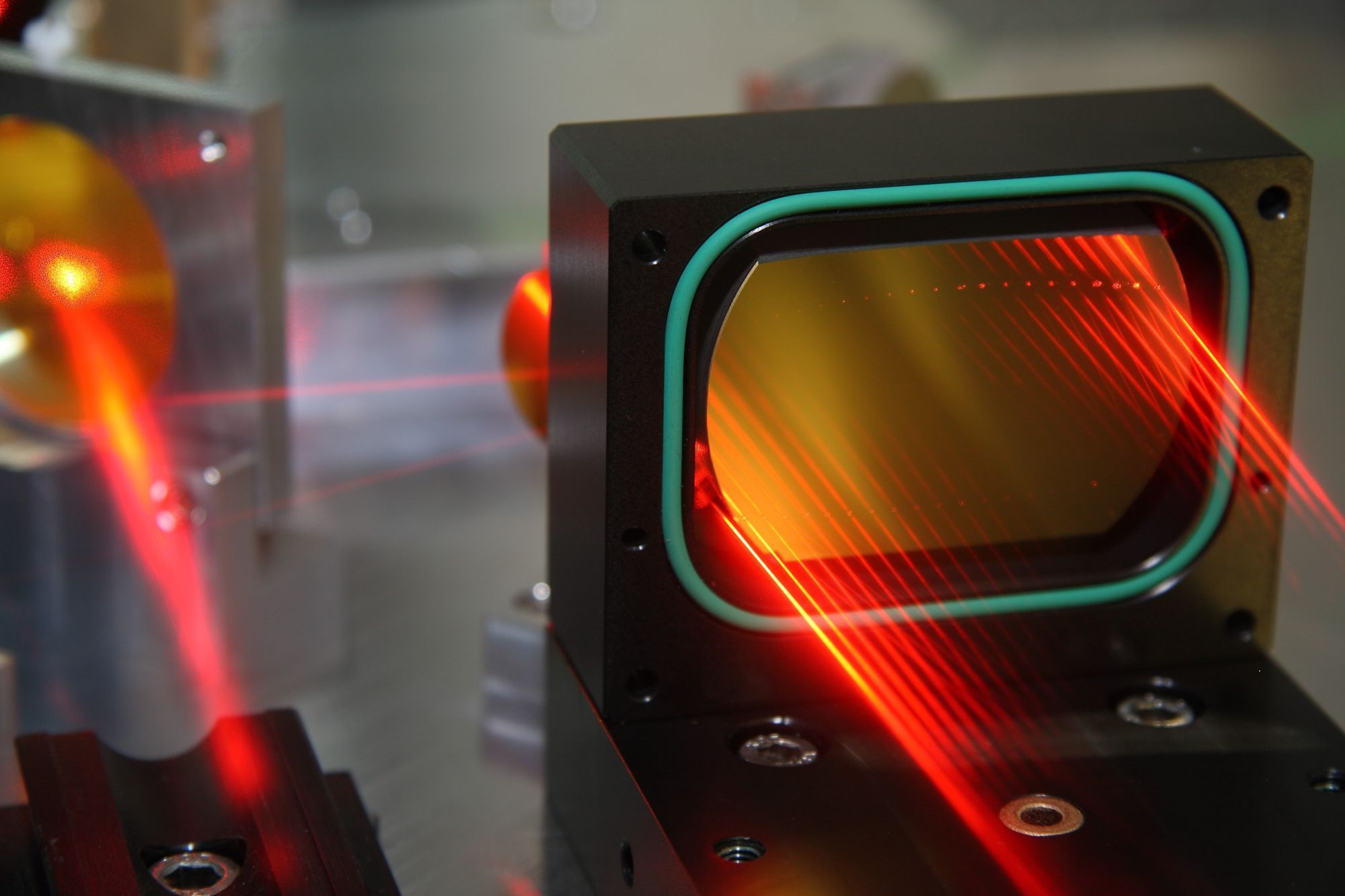

Today, lasers are among the most important tools of optics in research and industry. Laser-based spectrometers have clear advantages for demanding measurement tasks - for example in process analysis. Using a laser as light source, applications can be realized with high sensitivity and selectivity.

Advances in ICL, QCL and OPOs allow for more accurate measurements

Thanks to technological advances in interband cascade lasers (ICL), optical parametric oscillators (OPOs) or quantum cascade lasers (QCL), we are able to measure the composition of liquids and gases more sensitively and faster than ever before - not only in the laboratory but also in industrial processes. In addition to in-situ measuring systems or measuring systems with sophisticated sampling methods, remote gas measurements for leakage detection on gas pipelines over distances of 50 meters are now possible.

The extended spectral coverage of novel laser systems makes laser spectroscopy more flexible and opens up new areas of application. Lasers with an external optical resonator (EC laser), laser arrays and optical frequency combs are penetrating into areas of application that were previously reserved for classic broadband spectrometers or fourier transform spectrometers (FTIR). Gases under high pressures, larger molecules or liquids (by means of attenuated reflection, ATR) can be analyzed using broadband spectroscopy. Modern evaluation methods such as multi-component analysis and intelligent analysis methods provide reliable results even with complicated mixtures.

At Fraunhofer IPM, we develop laser spectroscopic gas measurement systems for a wide range of applications – tailored to the individual requirements of our customers. In joint projects, we offer a broad spectrum of options, from system predevelopment for measurement device manufacturers to specific measurement solutions for end customers, and from single devices to small series.